METAL PLATING

CADMIUM PLATING SERVICES

CADMIUM

Our cadmium plating service provides a wide array of advantages such a excellent corrosion resistance particularly in salt atmospheres, resistance to mold and bacterial growth, low electrical resistance and exceptional conductivity, galvanic compatibility with aluminum, excellent lubricity yielding good anti-galling and low friction properties, superior solderability, a good bonding surface for adhesives, and it works well either as a final finish or a paint base.

In combination with a chromate coating, cadmium can be dyed to many colors including clear, white silver, yellow and olive drab. Our cadmium electroplated coatings can be applied to steel, iron and other metals and is particularly well-suited for many military applications.

Cadmium Finish and Processing Options

Barrel Cadmium Plating

One of the many advantages offered by Northeast Metal Works is the quick cadmium electroplating turnaround time provided by our high capacity barrel cadmium electroplating line.

Conversion Coatings

Northeast Metal Works offers a hexavalent chromium conversion coating on our cadmium plated parts providing excellent corrosion resistance in marine and alkaline environments. The conversion coating not only enhances the corrosion resistance of the cadmium plated surface but can also alter the coating’s cosmetic appearance.

Corrosion Resistance

Northeast Metals Works cadmium plating service offers the capability to perform salt spray corrosion resistance testing according to ASTM B117 on our finished parts. Electroplated cadmium coated carbon steel parts with a hexavalent chromium coating will typically achieve 36 to 360 hours of protection against attack on the substrate in the salt spray test.

Baking

Northeast Metal Works operates several furnaces for the purpose of relieving hydrogen embrittlement in cadmium plated parts according to customer specifications.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are a key supplier of cadmium electroplated coatings for springs and rings in grenades for military applications. This military customer is very demanding. They have decided to partner with Northeast Metal Works due to our excellent quality and our ability to meet their specifications for salt-spray corrosion resistance and our heat treating capabilities which eliminate the risk of hydrogen embrittlement.

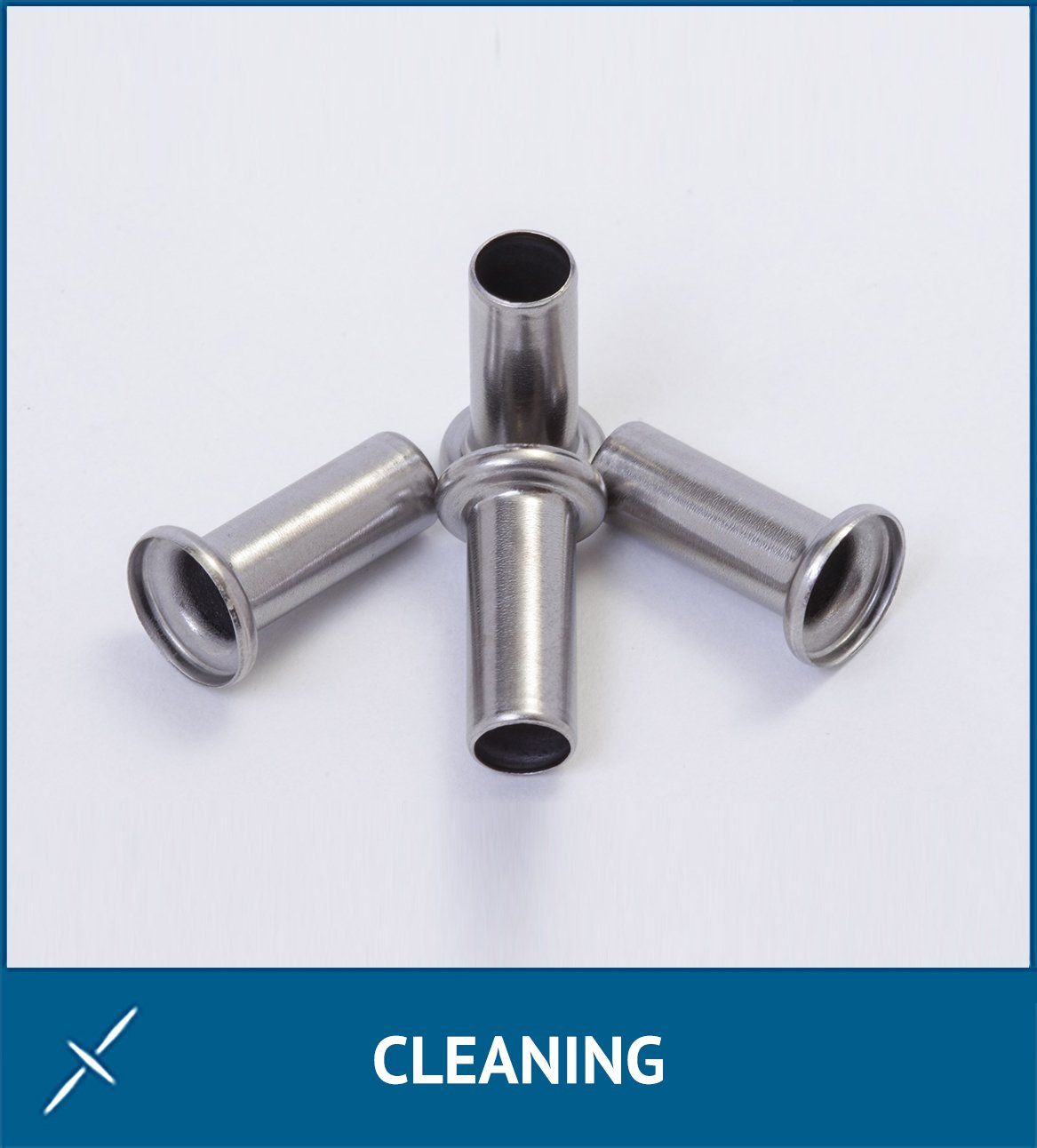

We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes. We offer quick turnarounds on our high volume barrel plating lines.

For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Cadmium Plating Specifications and Certifications

Northeast Metal Works cadmium electroplating service is fully registered to ISO9001:2015 and is capable of meeting specifications with its cadmium plating process which conform with ASTM B766-86,

Chrysler PS-182 and PS-754 and QQP-416.

Markets and Applications

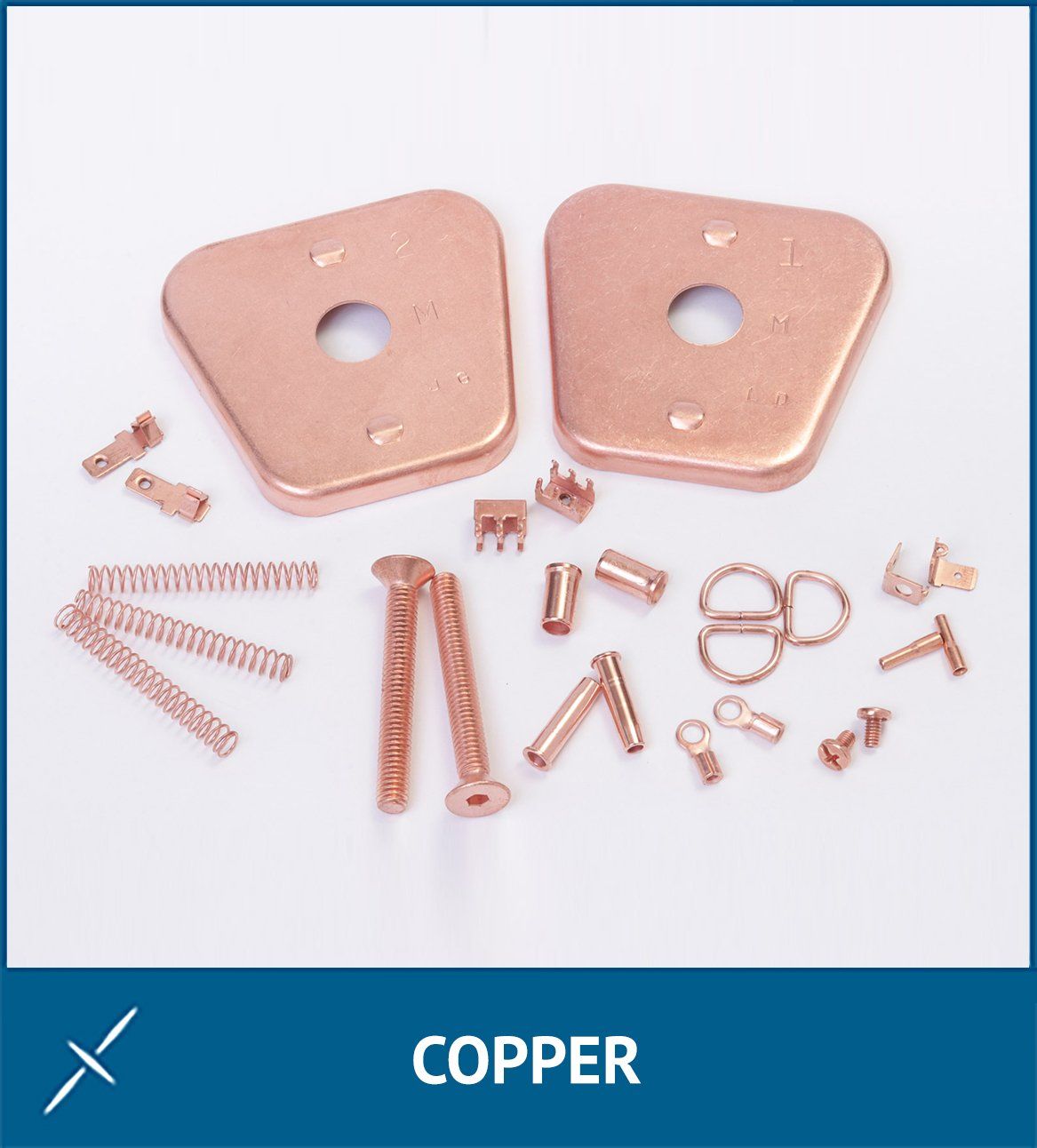

Northeast Metal Works has served a broad range of customers, markets and applications with its electroplated cadmium coatings including:

Markets:

Military

Automotive

Mining

Aerospace

Marine

Electronic

Electrical

Applications:

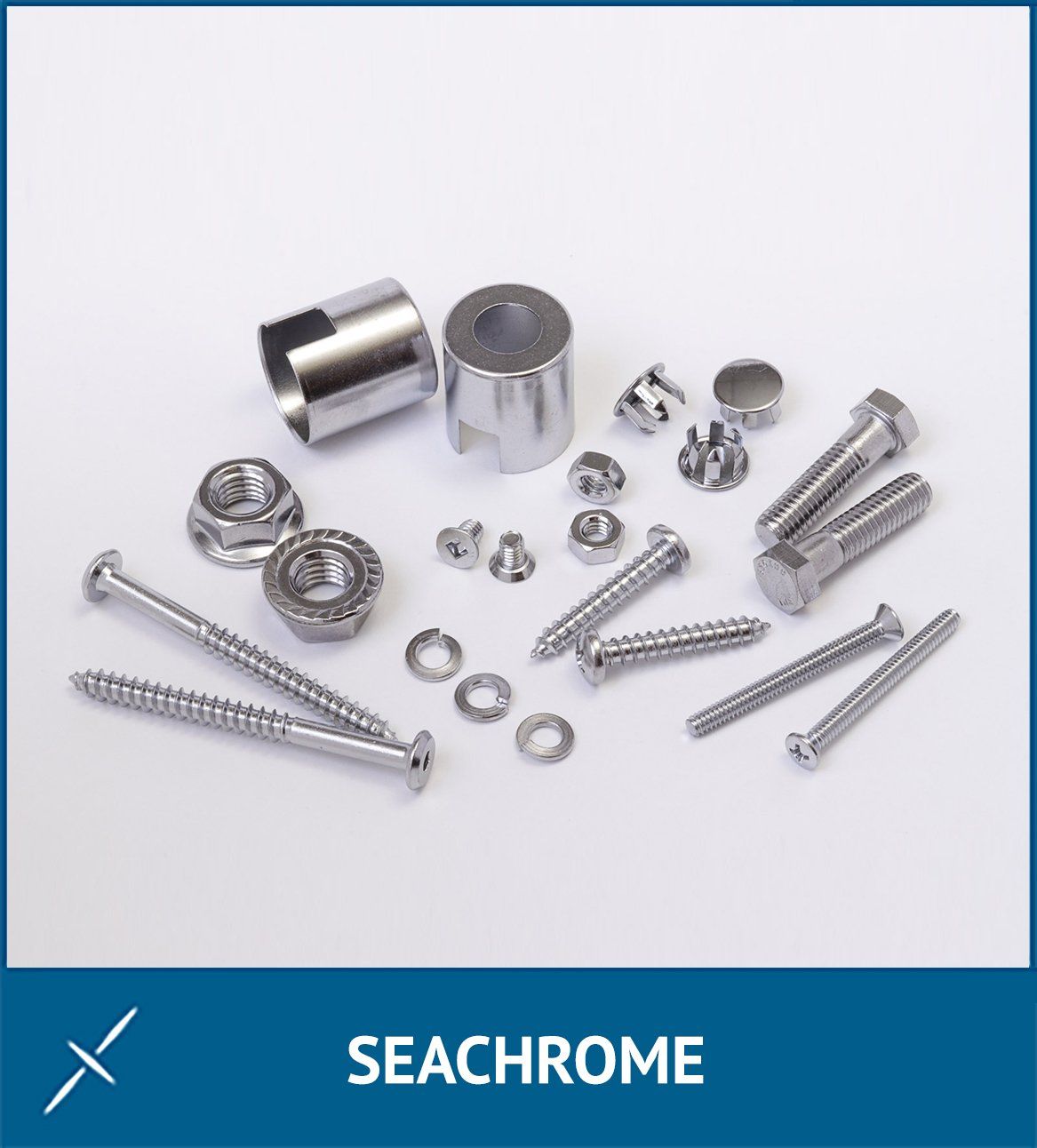

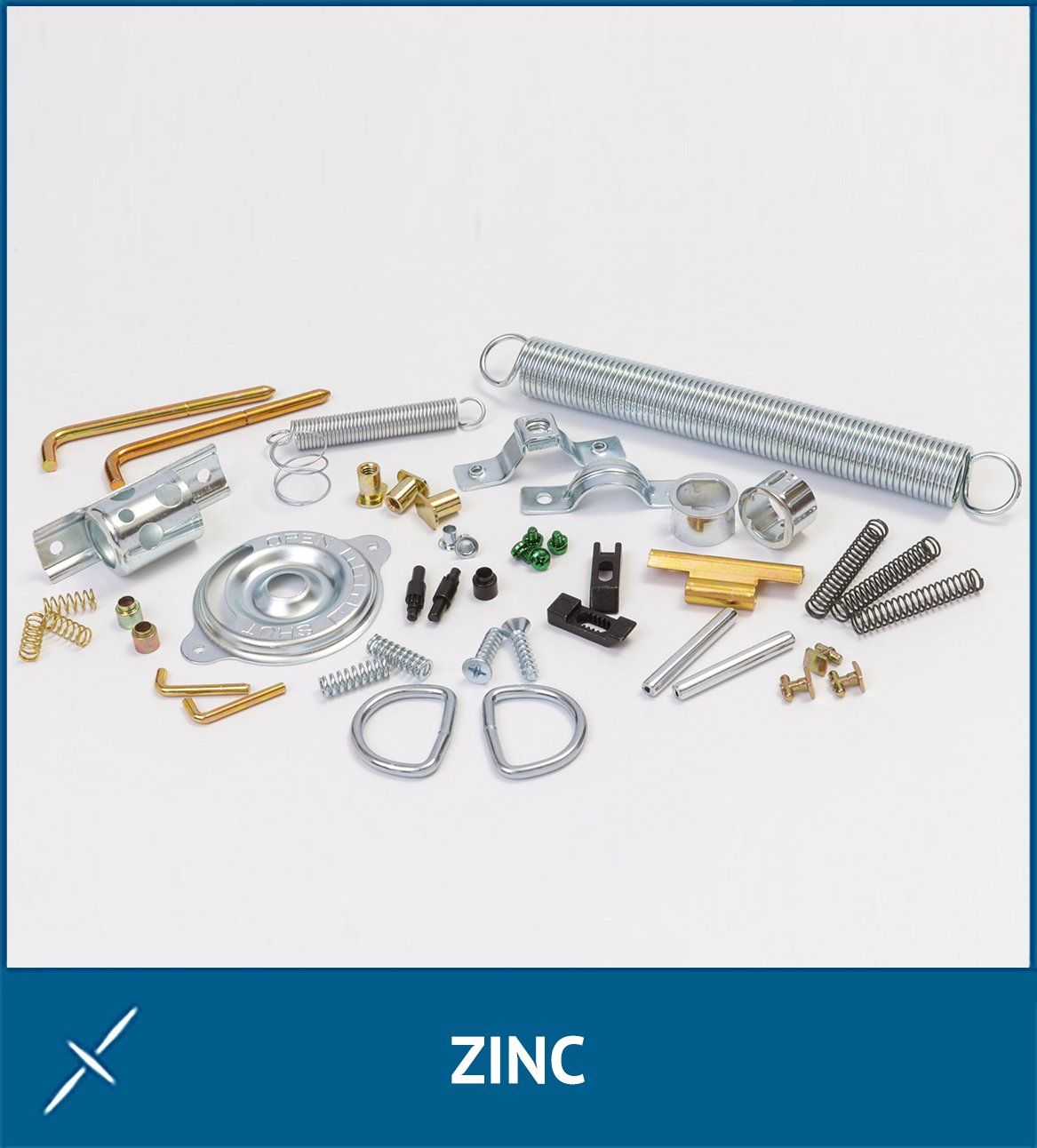

Fasteners

Bolts

Washers

Component parts

Metal fabrications

Substrates:

Ferrous

Non-Ferrous