METAL PLATING

POWDER COAT PLATING SERVICES

POWDER COAT

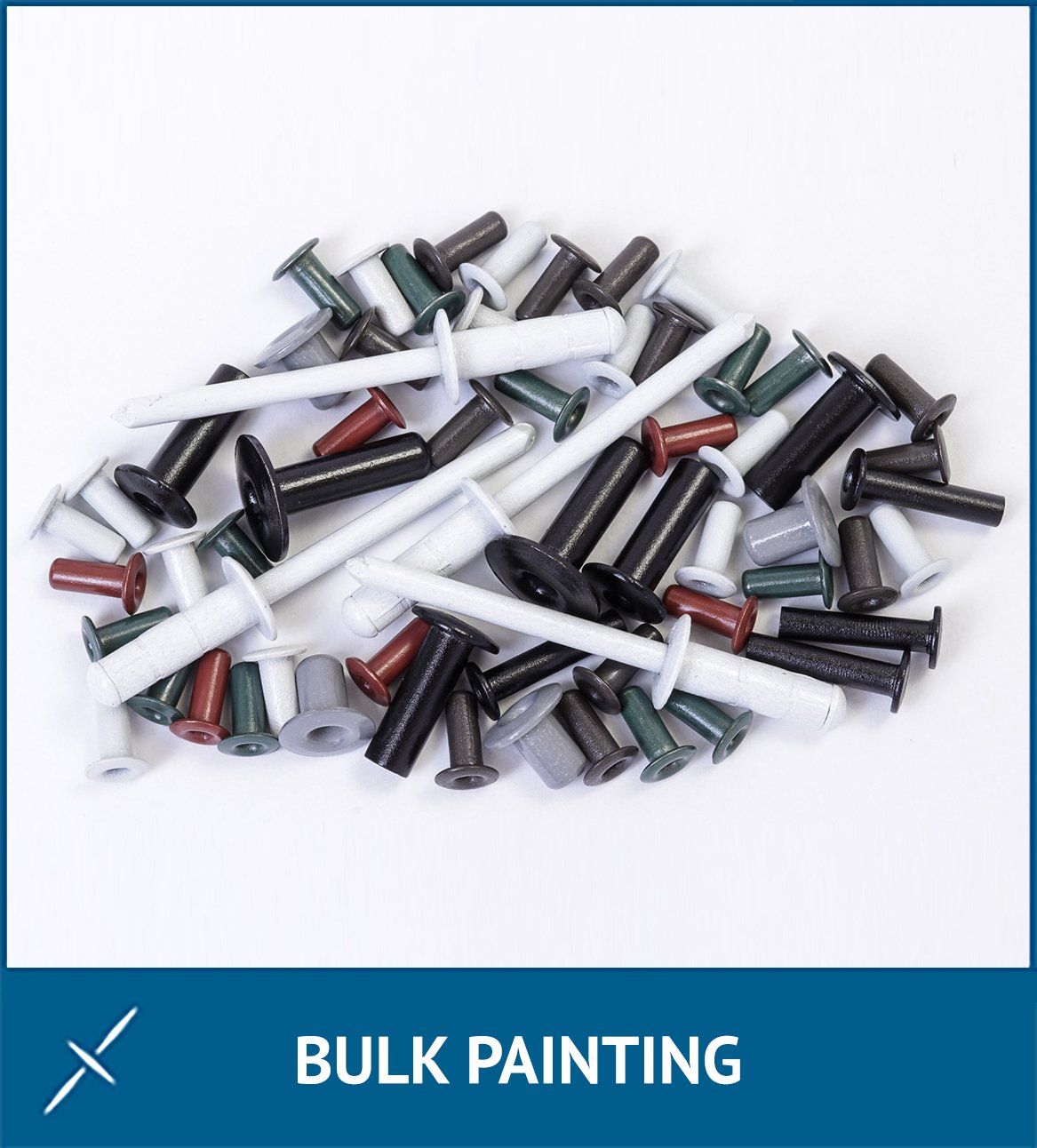

Powder coating is the fastest growing finishing technology in North America. Our powder coating is applied electrostatically as a free flowing dry powder and then cured under heat.

Powder coating protects the environment because it contains no solvents and releases little or no Volatile Organic Compounds (VOCs) into the atmosphere. Industrial powder coating is more durable than conventional paints because it can be applied as a much thicker coating without running or sagging.

Northeast Metal Works offers powder coating services in a wide variety of colors with matte, semi-gloss and glossy finishes.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are a leading supplier of powder coatings for holster clips for military and law enforcement application. We have developed this business due to our ability to customize the color requirements of these customers and deliver consistently colored parts at high volume.

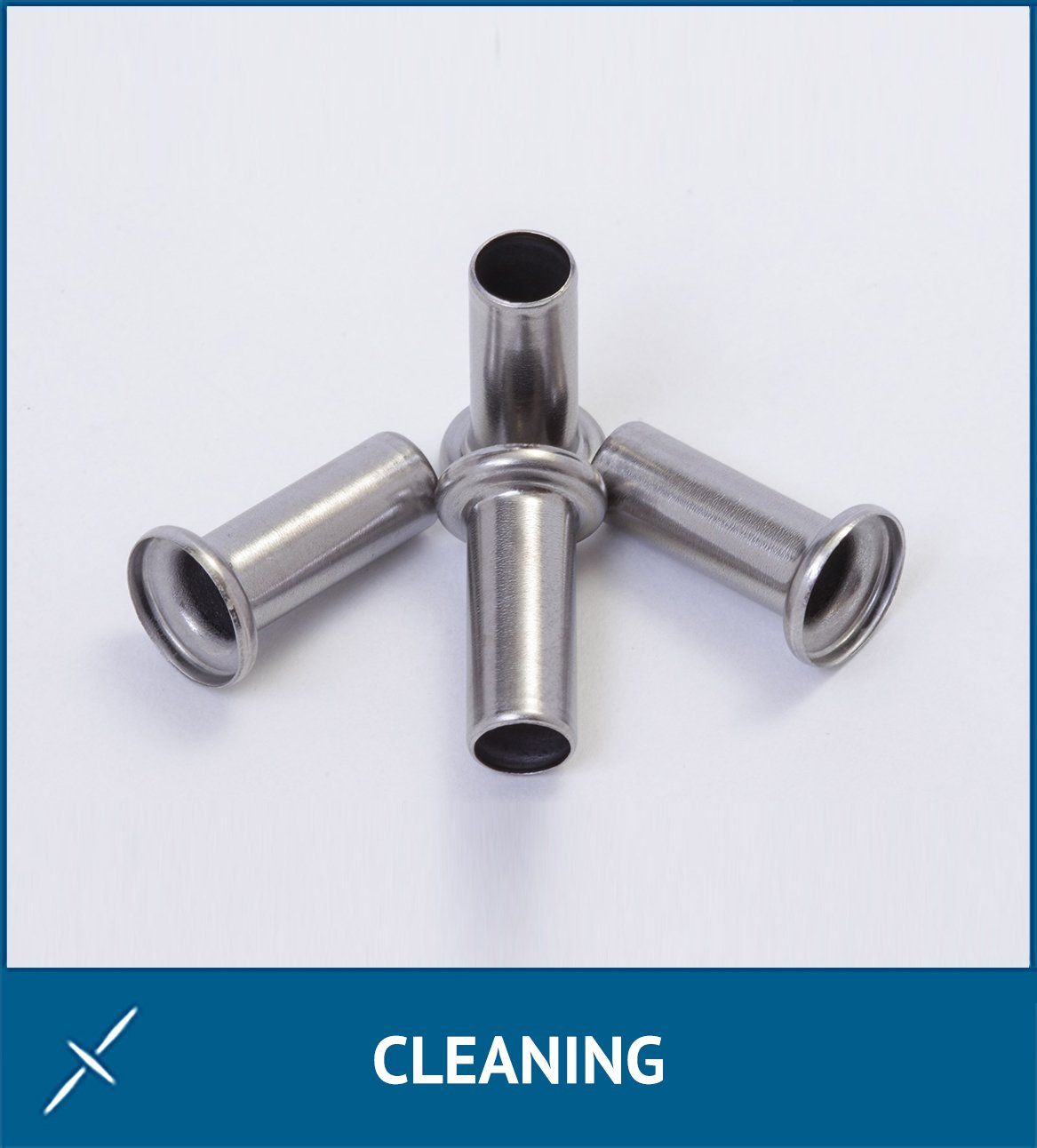

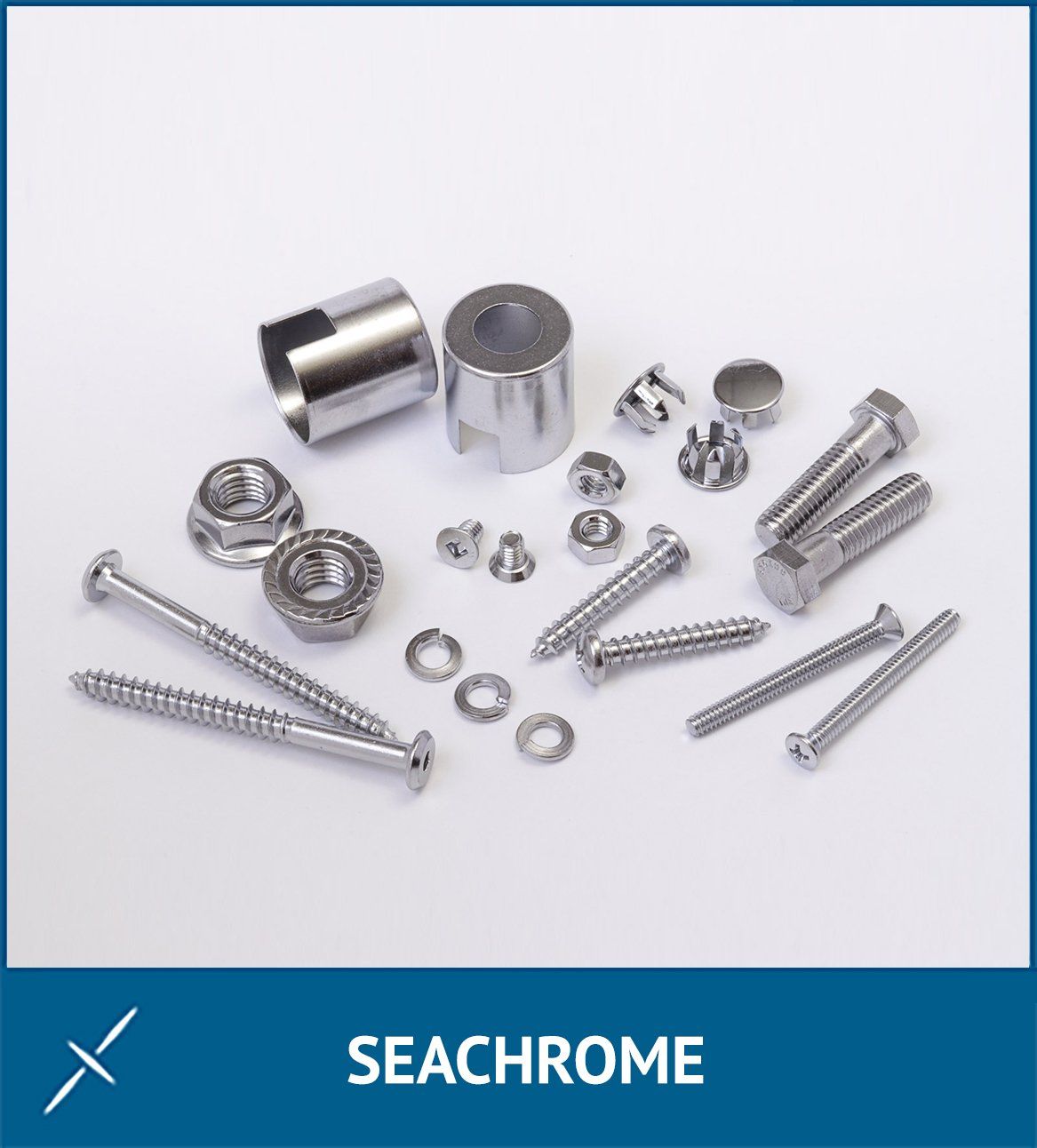

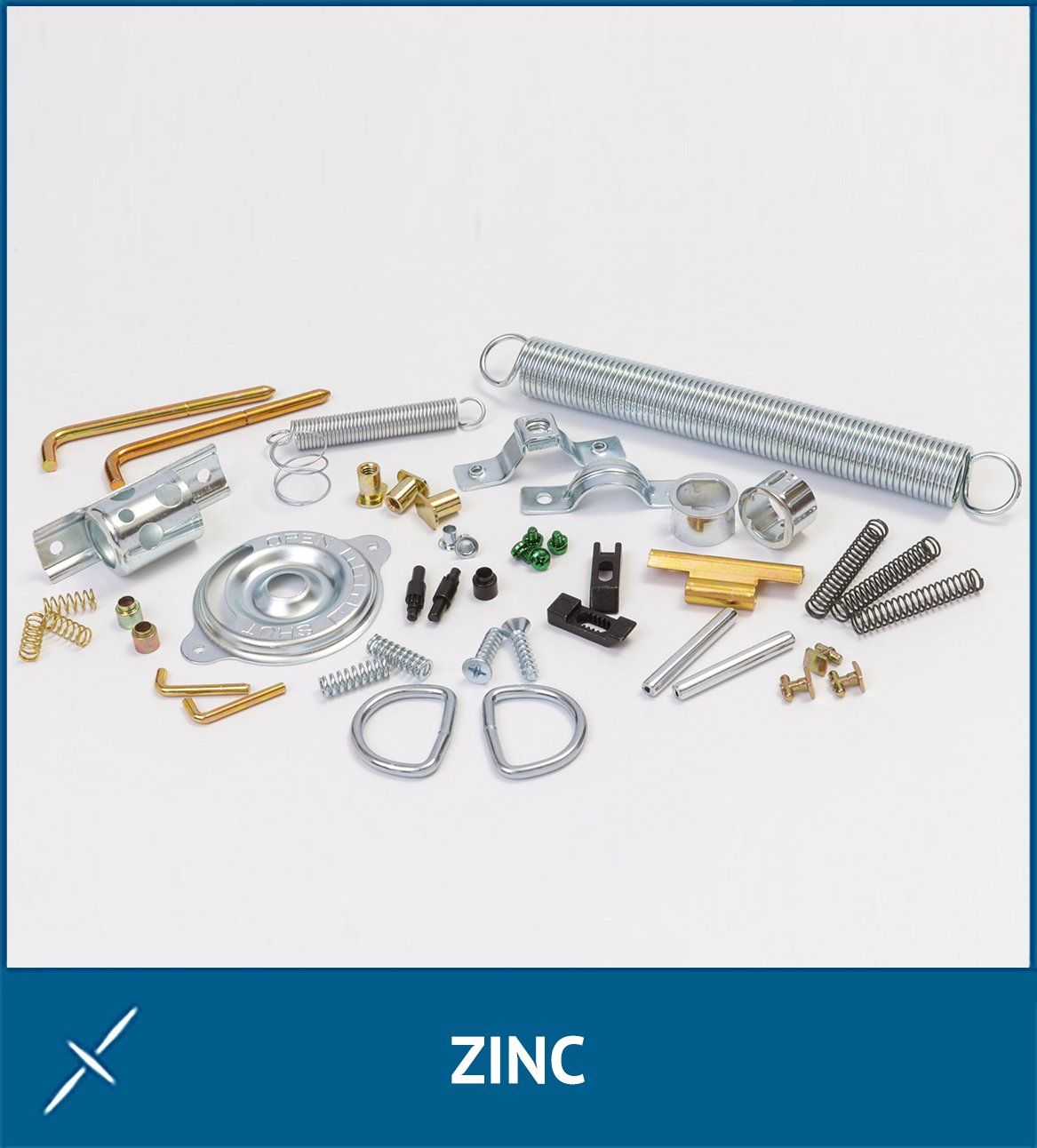

We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes. We offer quick turnarounds on our high volume barrel plating lines.

For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Specifications and Certifications

Northeast Metal Works powder coating service is fully registered to ISO9001:2015.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications with its powder coating service including:

Markets:

Automotive

Military

Appliances

Architectural

Applications:

Cosmetic finishes

Component parts

Consumer goods

Substrates:

Ferrous

Non-Ferrous