METAL PLATING

PASSIVATION PLATING SERVICES

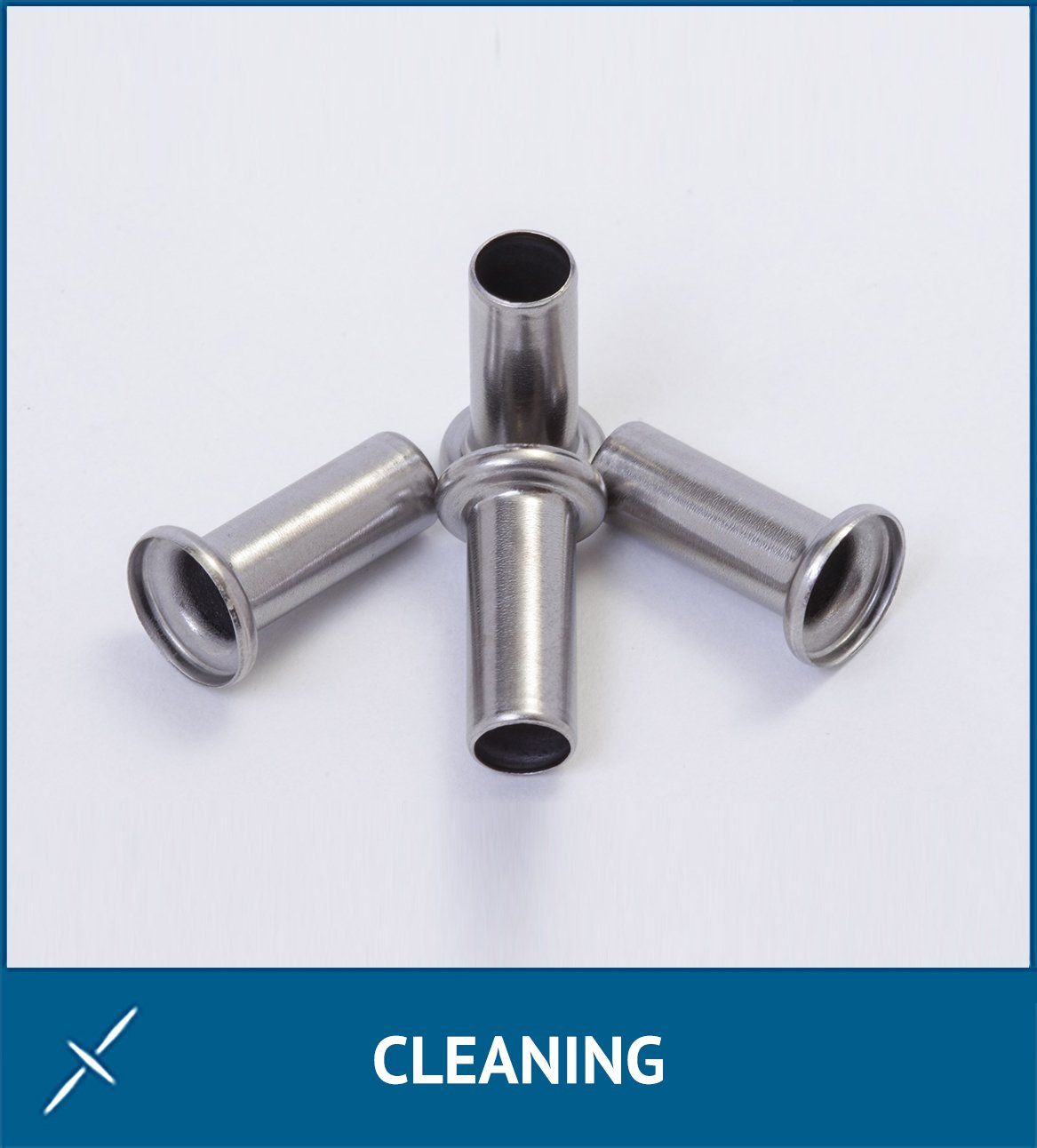

PASSIVATION

Our passivation services help to prevent corrosion and pitting of stainless steels. The name “stainless” steel might suggest that passivation is unnecessary. However, stainless steels are not completely impervious to rusting.

Finish and Processing Options

Passivation

Northeast Metal Works stainless steel passivation process creates an oxide layer on the surface of the part that protects the surface from rust and corrosion. The actual passivation process used is tailored to your specific stainless steel grade and application.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are a leading supplier of stainless steel passivation services for fasteners in aerospace applications. We differentiate ourselves with our unique capability to passivate parts on either our barrel line, our rack line or our basket line depending on the customers volume needs.

We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes.

We offer quick turnarounds on our high volume barrel plating lines. For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Passivation Specifications and Certifications

Northeast Metal Works passivation service is fully registered to ISO9001:2015 and complies with ASTM A967 and QQP-35C.

Markets and Applications

Our Company has served a broad range of customers, markets and applications with its passivation service including:

Markets:

Automotive

Medical

Military

Aerospace

Industrial

Chemical Process Industry

Textile

Marine

Electronic

Applications:

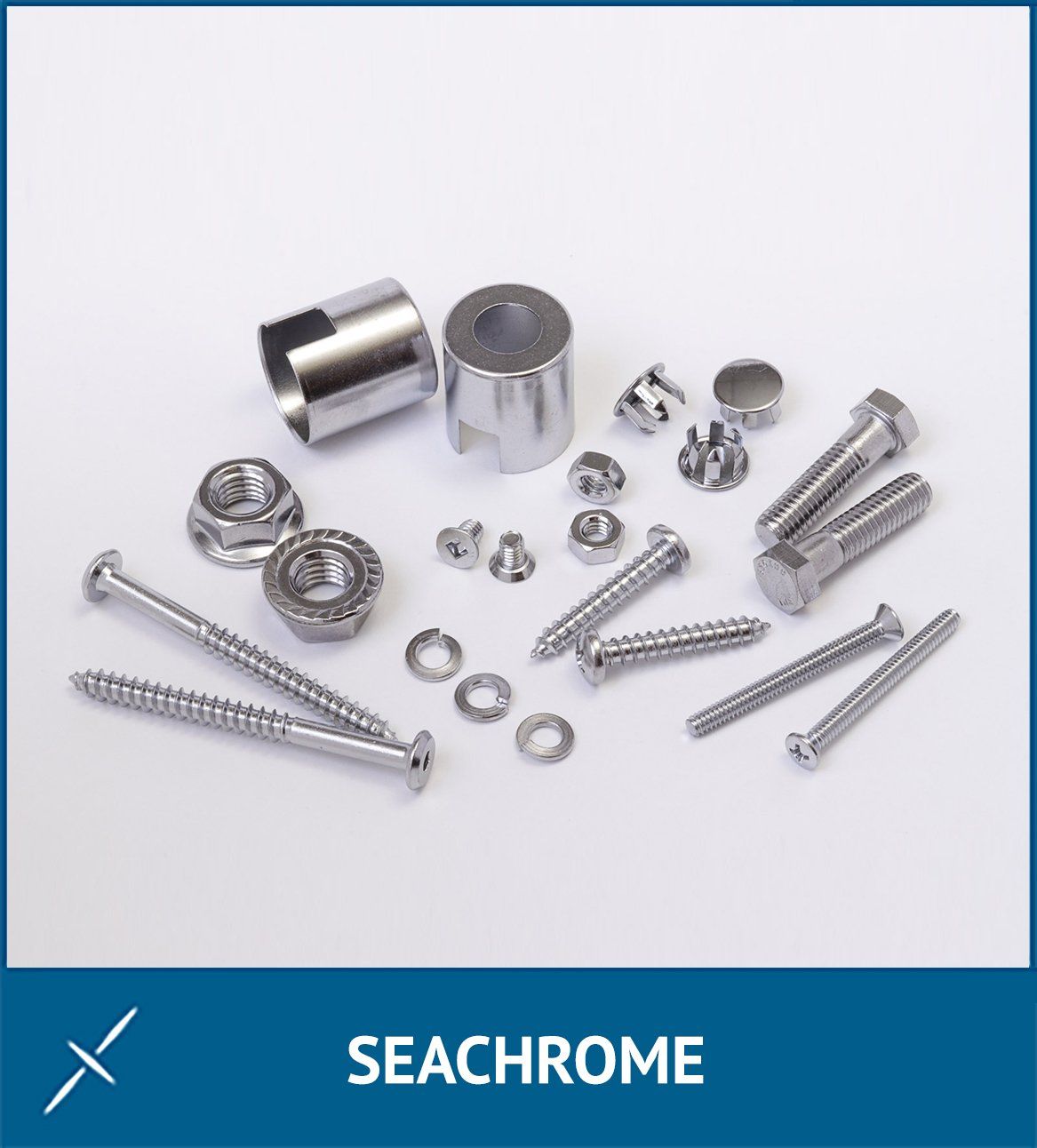

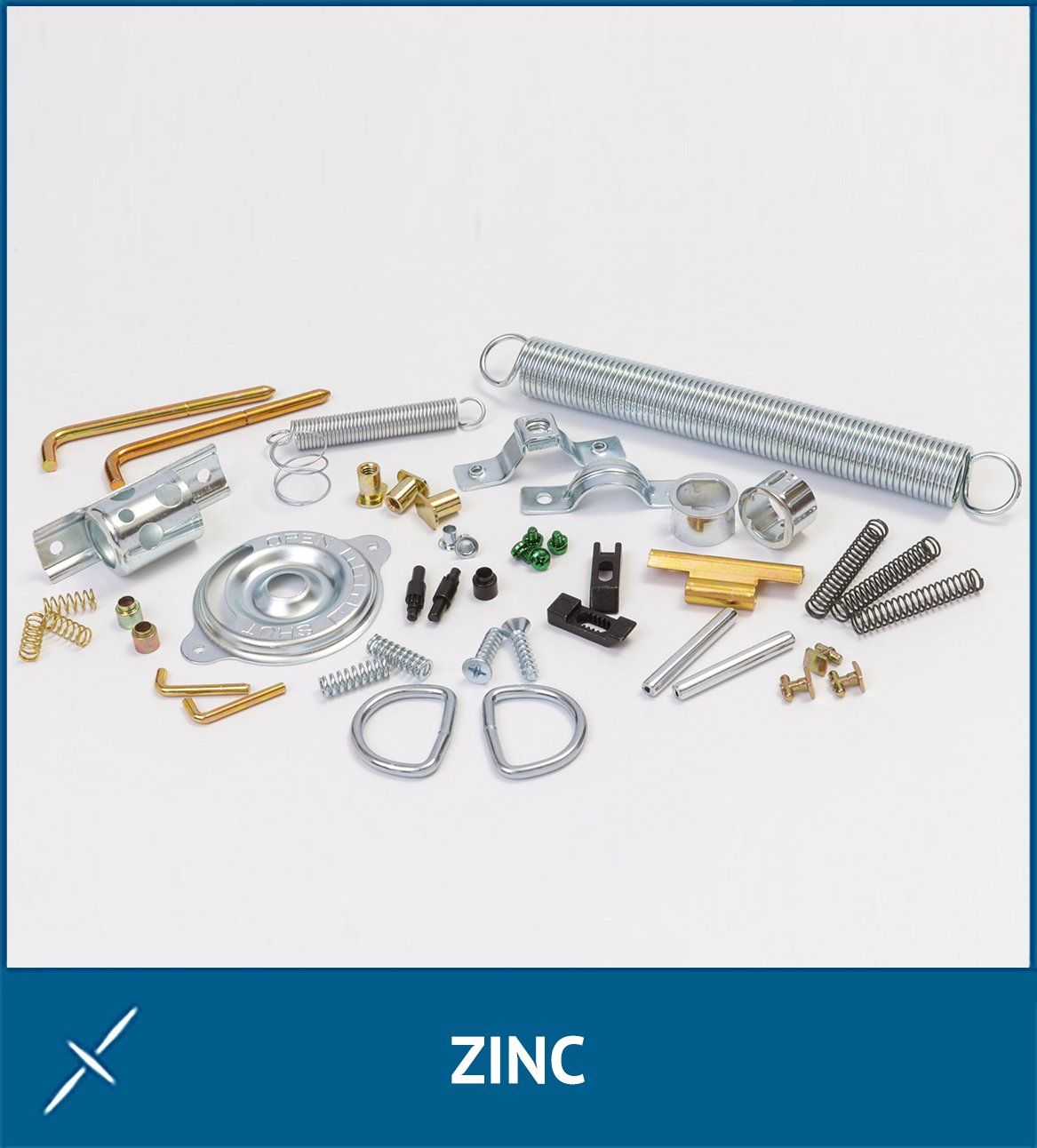

Fasteners

Bolts

Washers

Medical devices

Dental devices

Component parts

Substrates:

Ferrous