METAL PLATING

NICKEL PLATING SERVICES

NICKEL

Our nickel plating service provides a wide range of alternatives depending on the application. We meet all of the standards for electroplated nickel coatings for both engineering, decorative and barrier coatings in both barrel and rack plating applications.

Our electroplated nickel coating service can satisfy several important functional properties for engineering applications including hardness, strength, ductility, wear resistance, load bearing characteristics, corrosion resistance, heat scaling resistance, fretting resistance and fatigue resistance.

Our decorative electroplated nickel coating offers a high luster finish while electroplated nickel used in barrier applications provides excellent corrosion resistance. In addition to bright, electroplated nickel coatings, we offer electroless nickel coatings and sulphamate nickel coatings.

Nickel Plating Finish and Processing Options

Barrel and Rack Plating

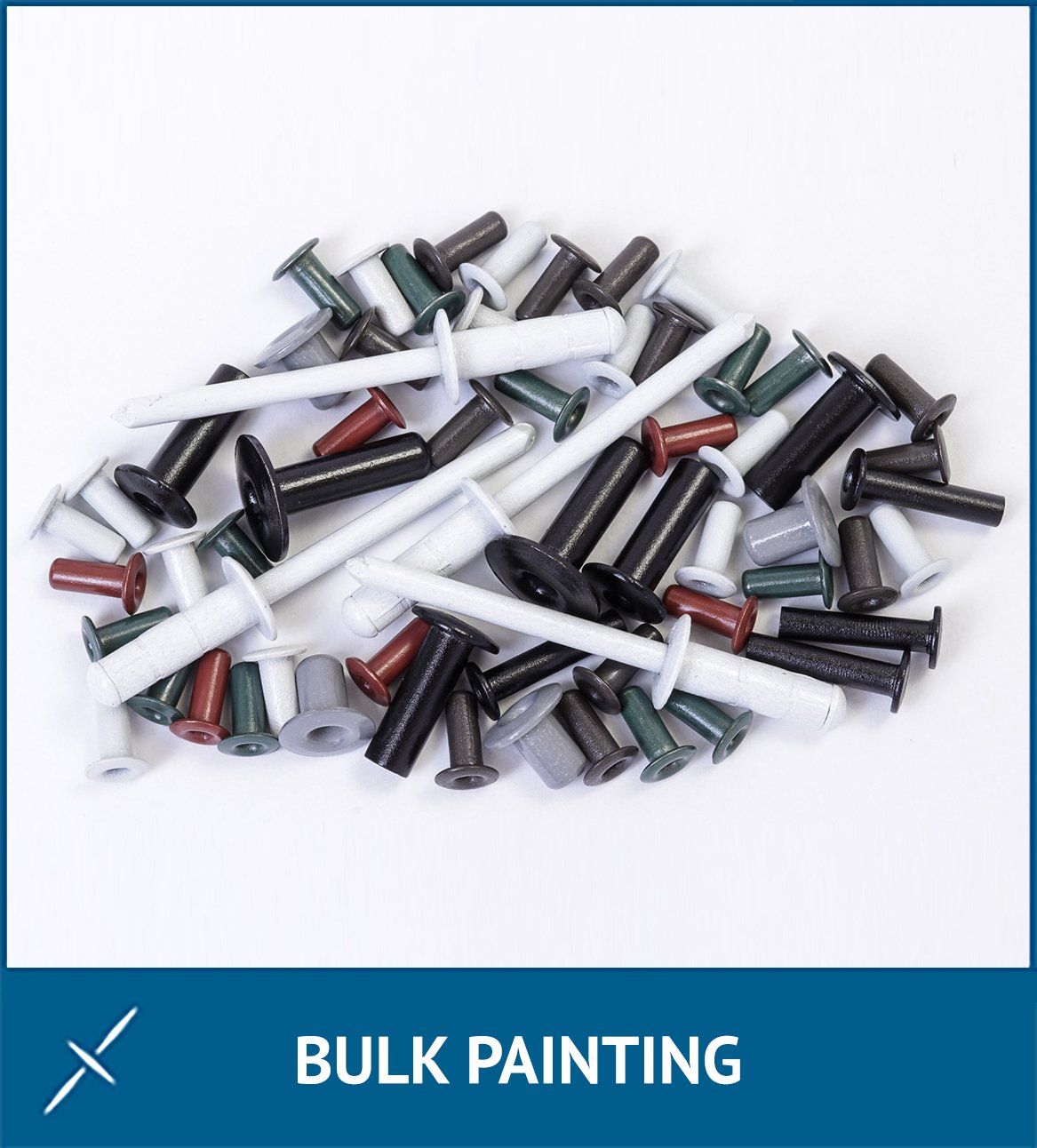

One of the advantages offered by Northeast Metal Works is our ability to accommodate multiple part designs with our capability to apply electroplated nickel coatings on either our barrel nickel electroplating line or our rack electroplating line. High volume parts that can be processed in bulk are good candidates for our barrel electroplating lines. While more intricate part designs or heavy parts can be individually processed on our automatic rack nickel electroplating line.

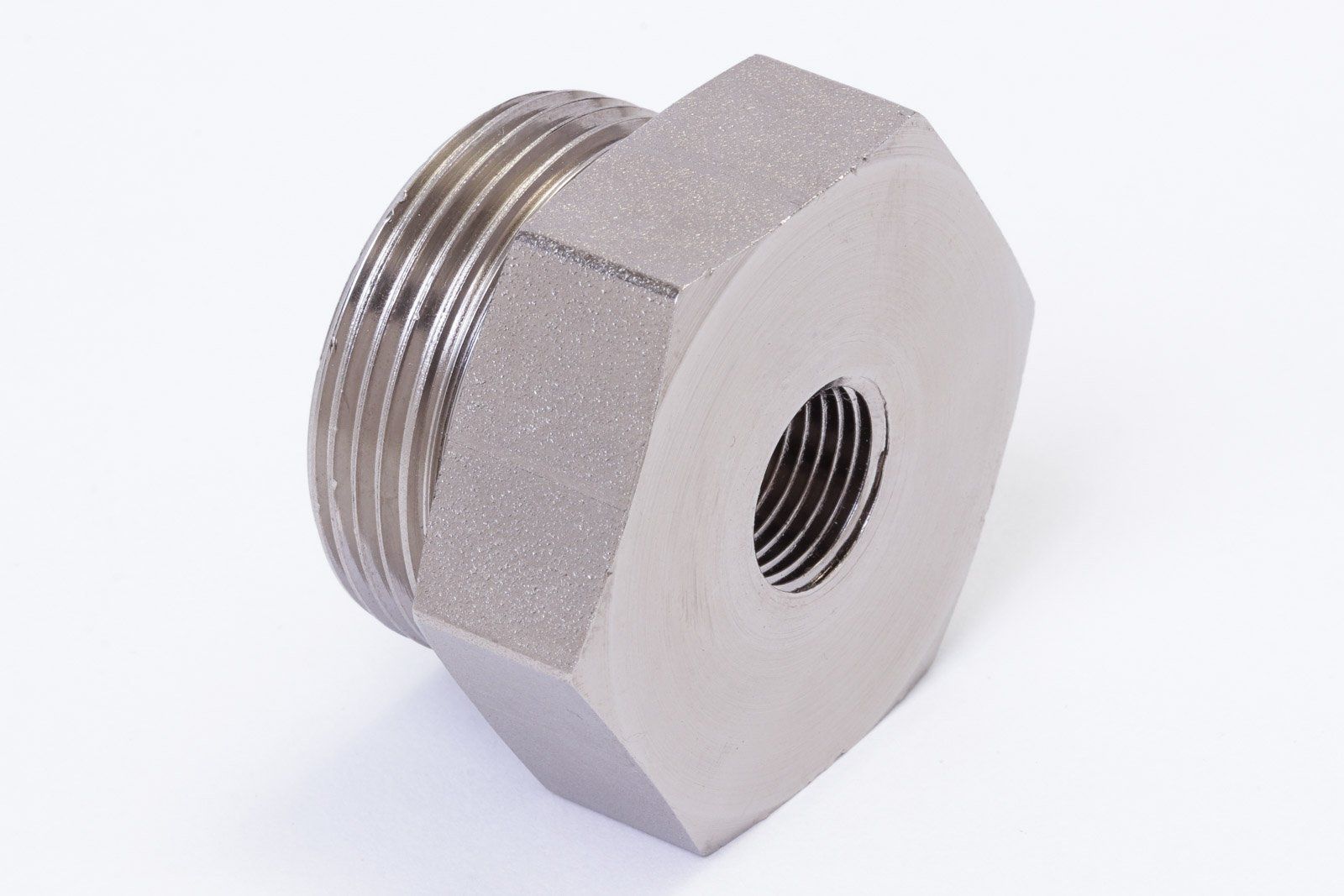

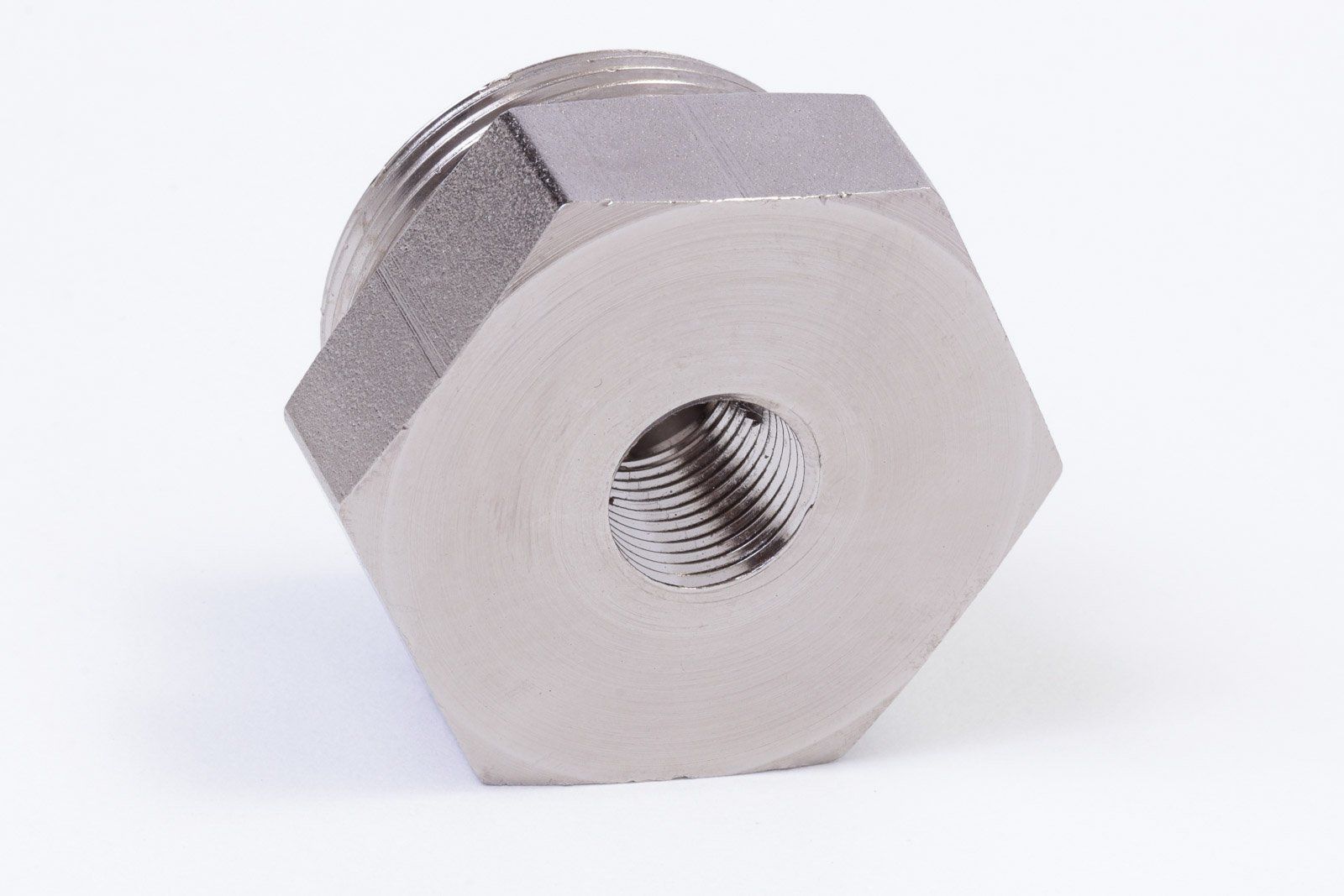

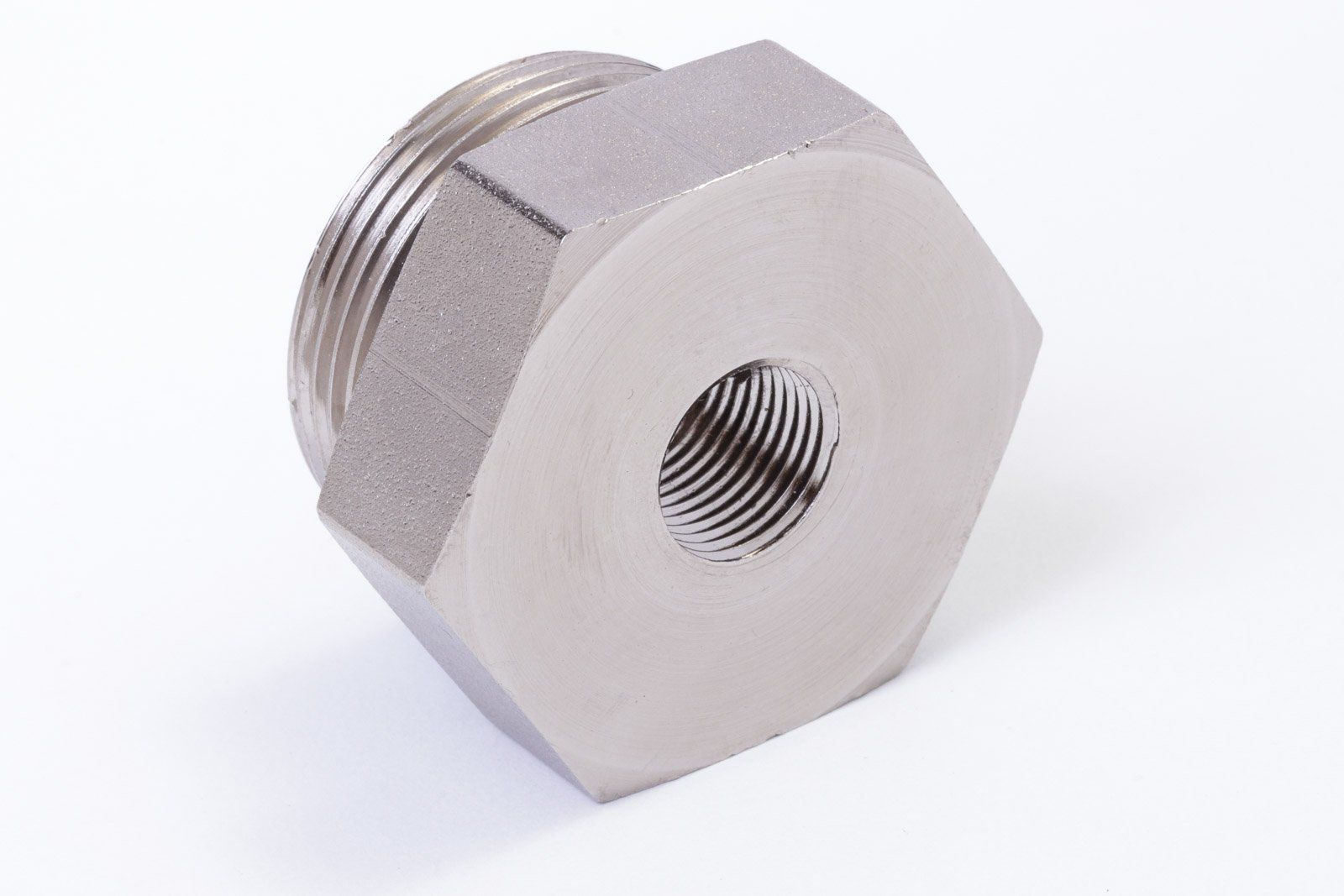

Electroplated (Electrolytic) Nickel

One of the advantages offered by Northeast Metal Works is our ability to offer quick turnarounds for electroplated nickel coatings in our high capacity automated barrel nickel electroplating line. The shiny, bright silver, mirror-like finish produced on our electroplated nickel line provides an excellent cosmetic finish for many applications including automobile components, plumbing fixtures and electronic components.

Electroless Nickel

Northeast Metal Works offers low, mid and high phosphorous content electroless nickel coatings. Electroless nickel coating does not require an electric current to plate nickel on a substrate.

One of the advantages of electroless nickel coating is that given the absence of an electric current there is no concern about different plating thicknesses in areas with high current density versus low current density. As a result, electroless nickel coatings tend to be very uniform in thickness.

The phosphorous content of the electroless nickel bath can impact the coating’s corrosion resistance, magnetic properties, lubricity, electrical conductivity, solderability and wear resistance which is why we offer several options in phosphorus level to meet your specific needs. Our electroless nickel coatings have found applications in many markets including marine, automotive, industrial and many others.

Sulphamate Nickel

Sulphamate nickel electroplating uses a 99.9% pure nickel deposit rather than the traditional nickel sulfate used in electroless nickel plating. Because this is a much higher concentration of nickel it lends added advantages to the surface durability. This 99.9% pure nickel coating delivers superior corrosion resistance, thanks to its purity, density and highly consistent deposit structure. Sulphamate nickel coating has good resistance to high temperature oxidation, high tensile strength and ductility and is easily machinable and solderable. Sulphamate nickel has a dull gray finish.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

As a result of our service excellence, we are the sole source for nickel plating of all of the domestically produced safety pins in the U. S. We were awarded this business due to our consistent quality and our ability to handle high volumes of this product on our high capacity barrel plating lines.

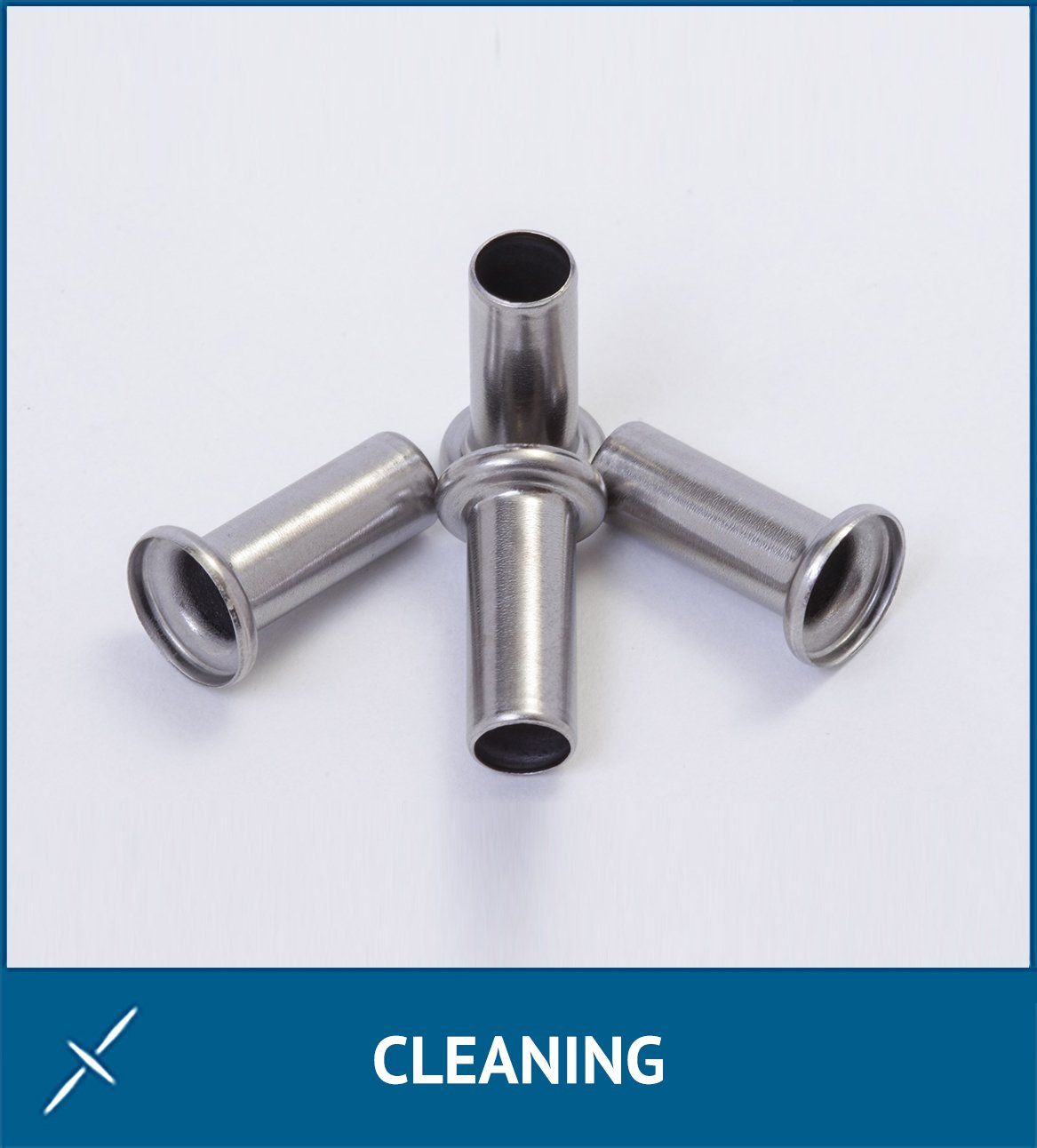

We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes. We offer quick turnarounds on our high volume barrel plating lines.

For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Nickel Plating Specifications and Certifications

Northeast Metal Works nickel plating service is fully registered to ISO9001:2015 and is capable of meeting specifications ASTM B-689, ASTM B-733 and GM4254M, with its nickel coating processes.

Markets and Applications

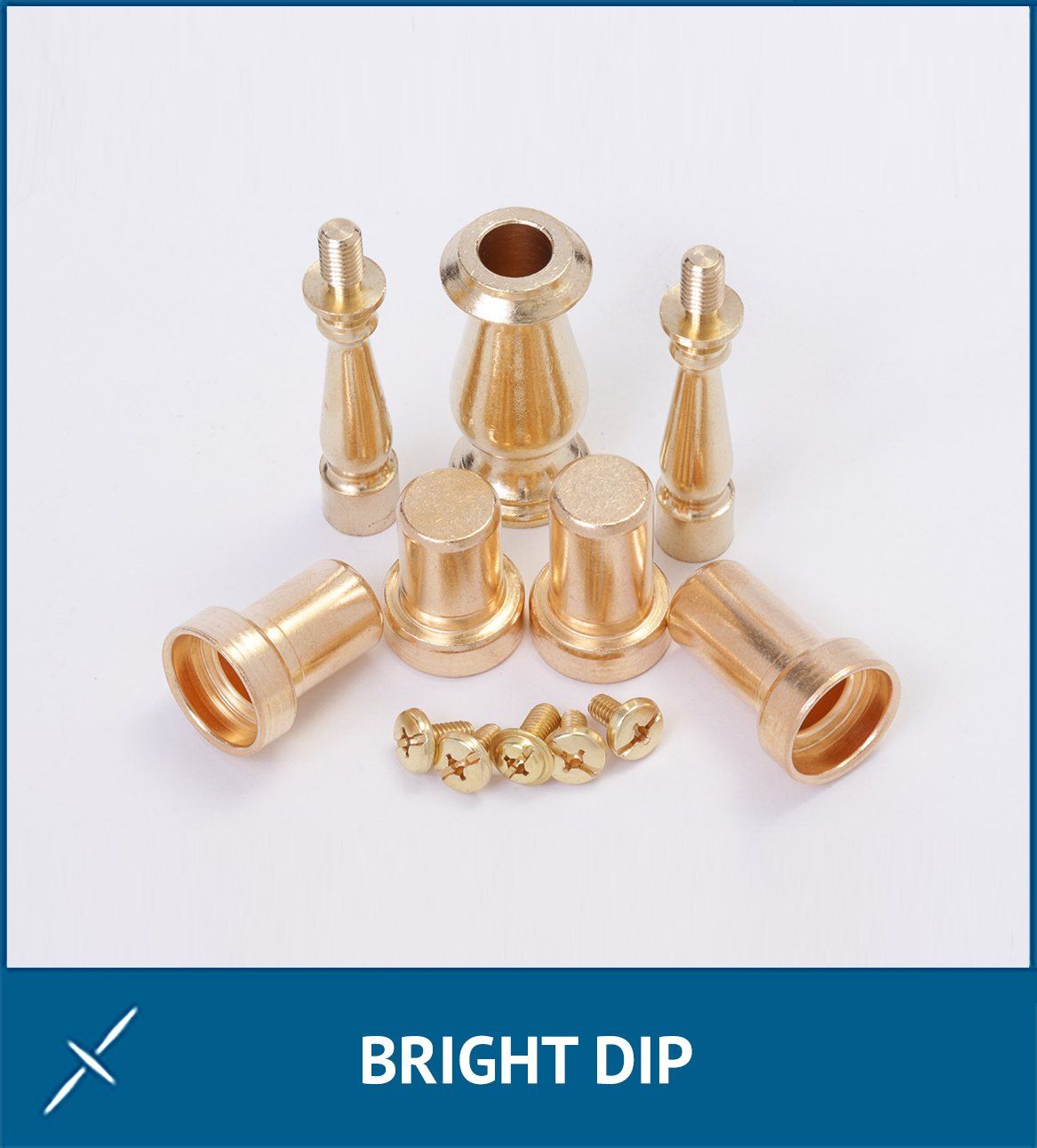

Our Company has served a broad range of customers, markets and applications with its nickel coatings including:

Markets:

Automotive

Medical

Military

Aerospace

Industrial

Chemical Process Industry

Textile

Marine

Electronic

Applications:

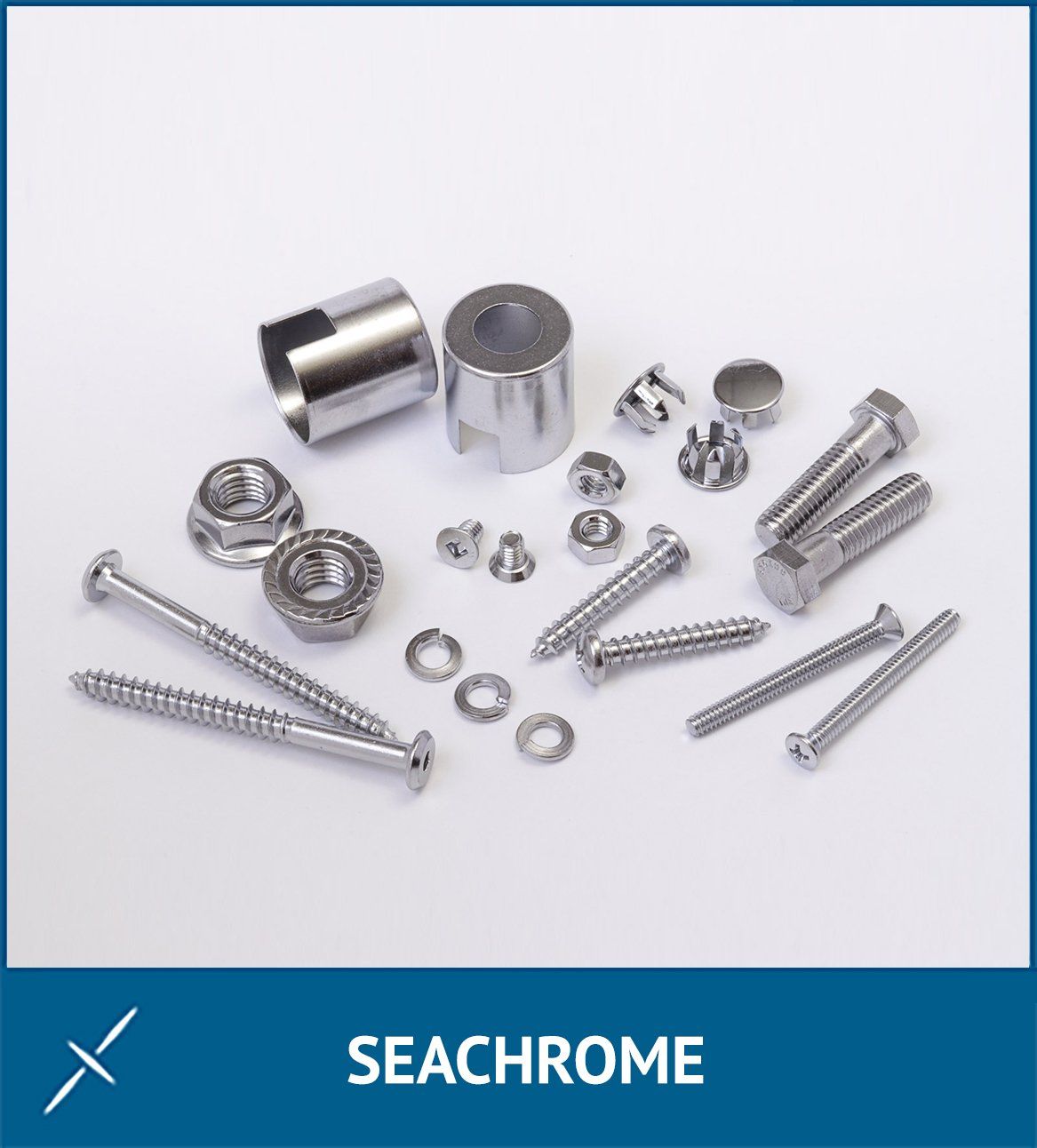

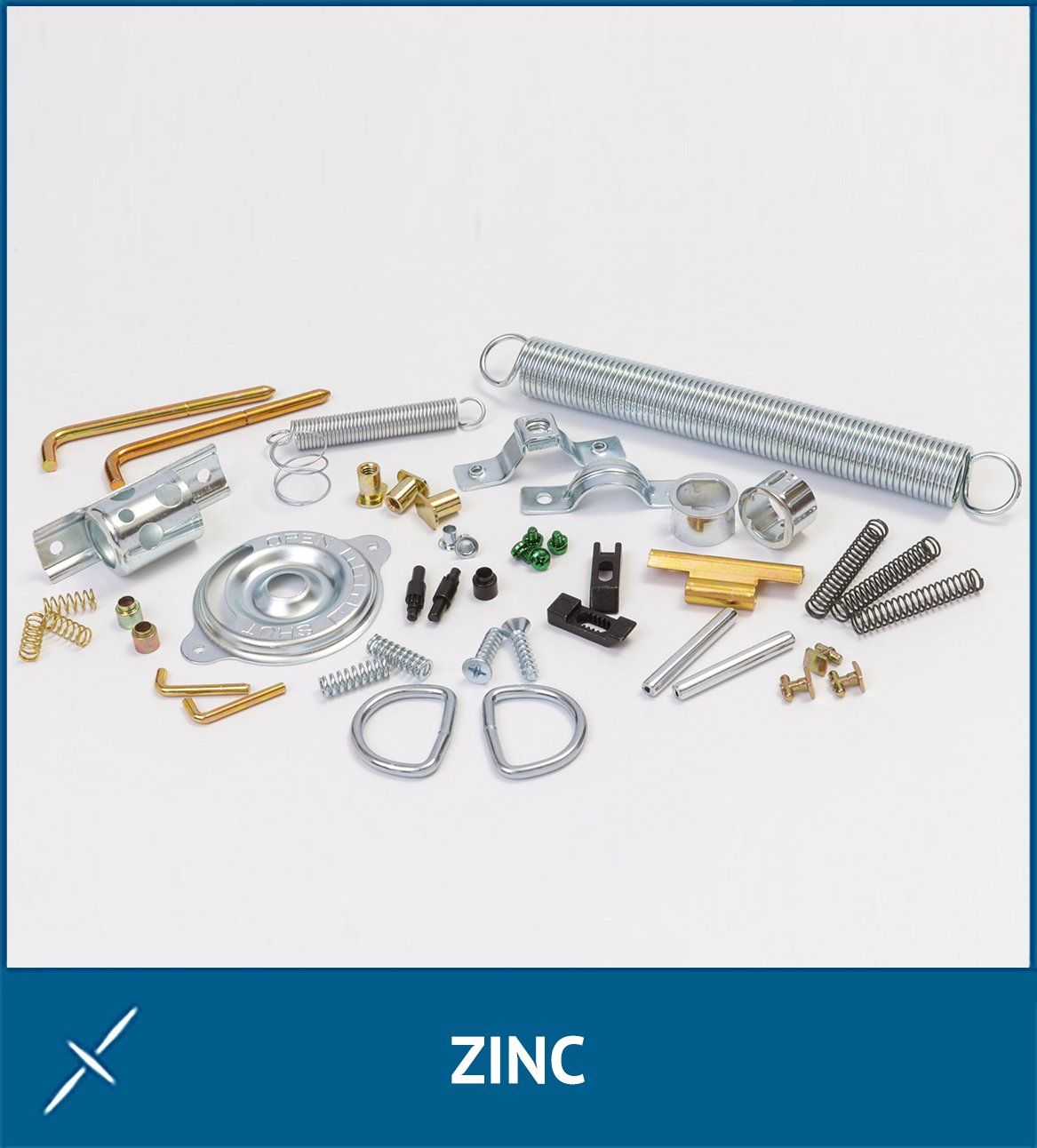

Fasteners

Bolts

Washers

Safety Pins

Medical devices

Dental devices

Component parts

Metal fabrications

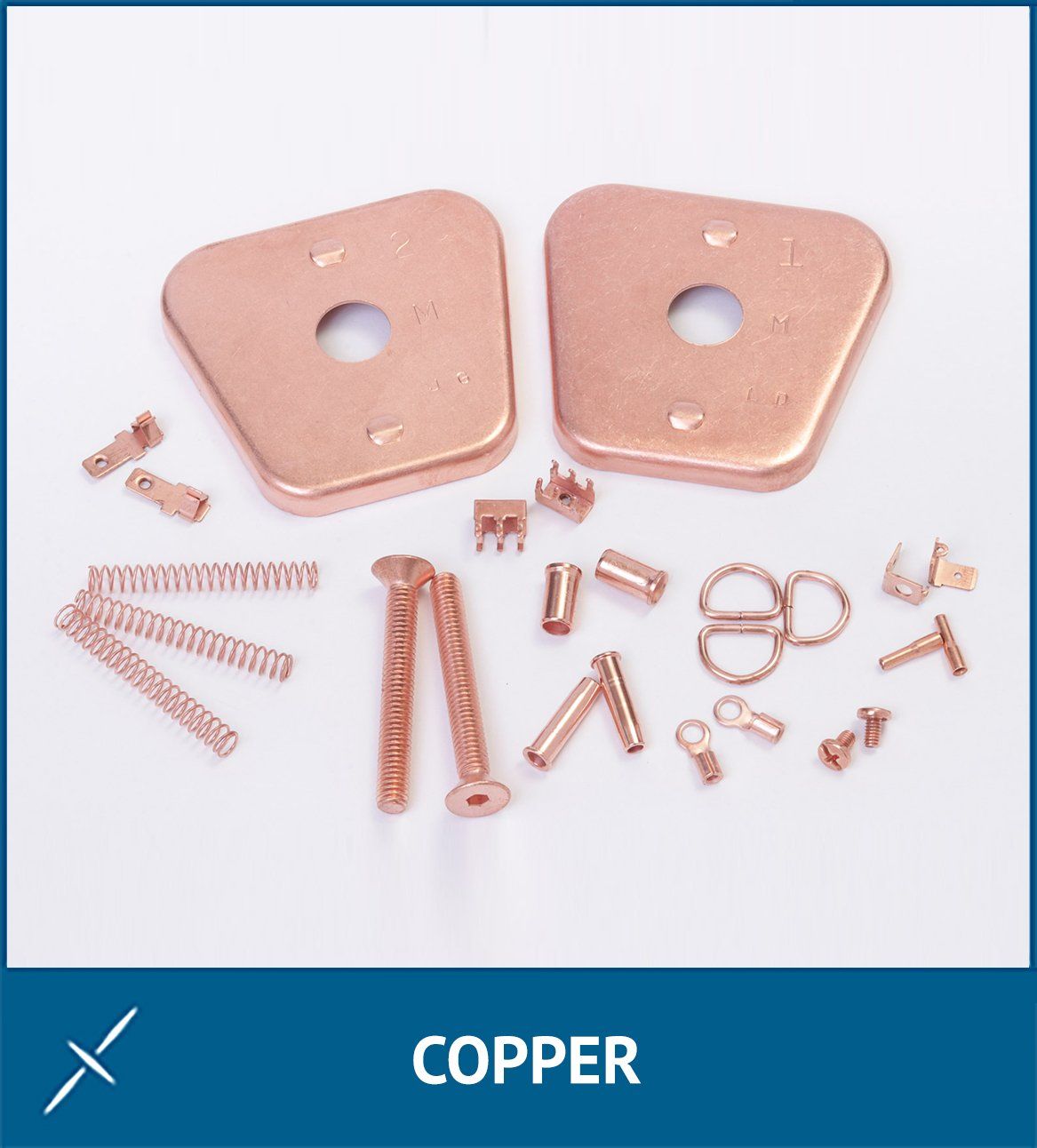

Substrates:

Ferrous

Non-Ferrous