METAL PLATING

TIN PLATING SERVICES

TIN

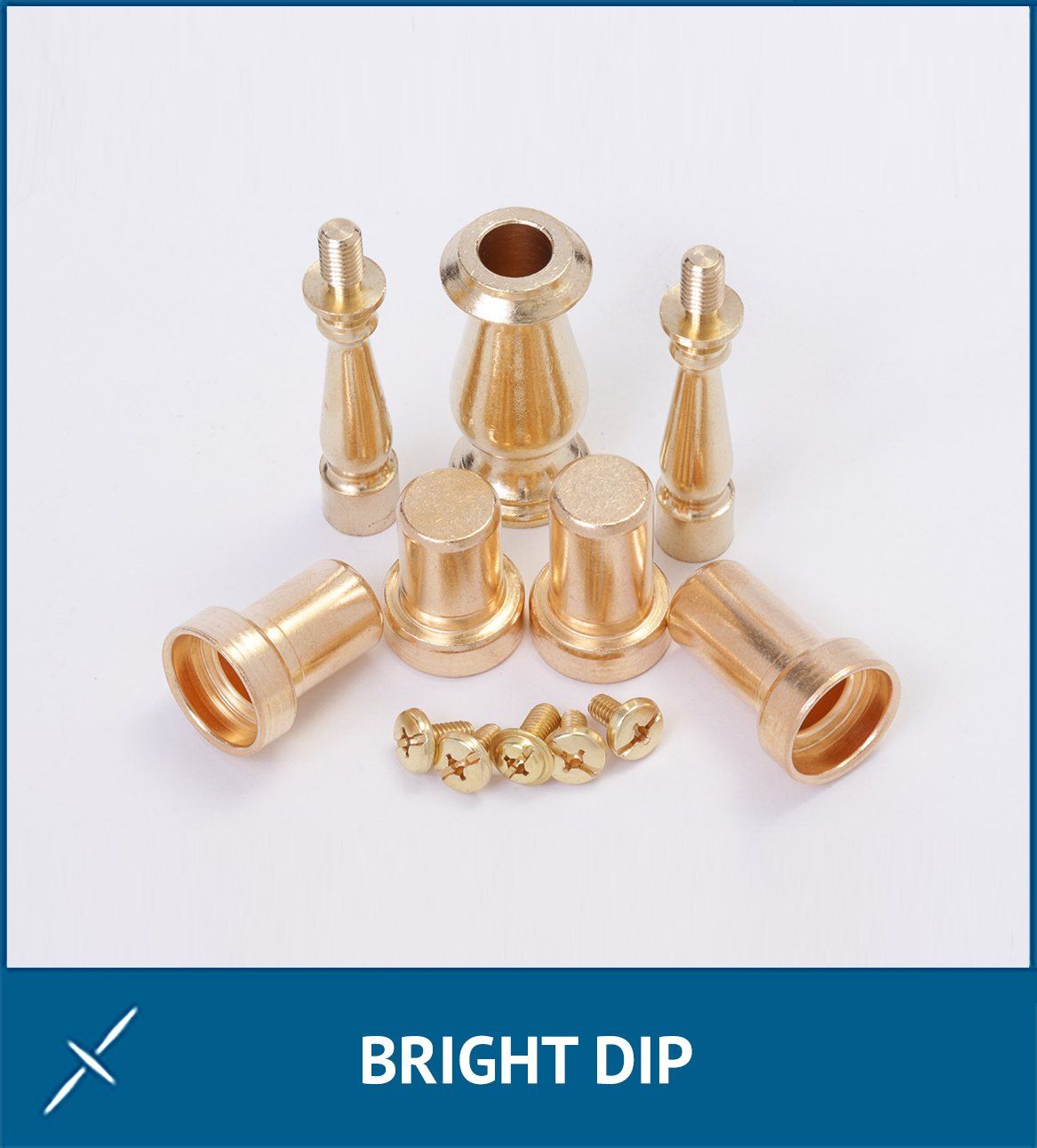

Our tin plating services provide either a bright silver finish or a matte finish for many different applications.

Electrodeposited coatings of tin are used to provide a low contact-resistance surface, protect against corrosion, facilitate soldering, provide anti-galling properties and be a stop-off coating in the nitriding of high-strength steels.

Finish and Processing Options

Barrel Electroplated Tin Coatings

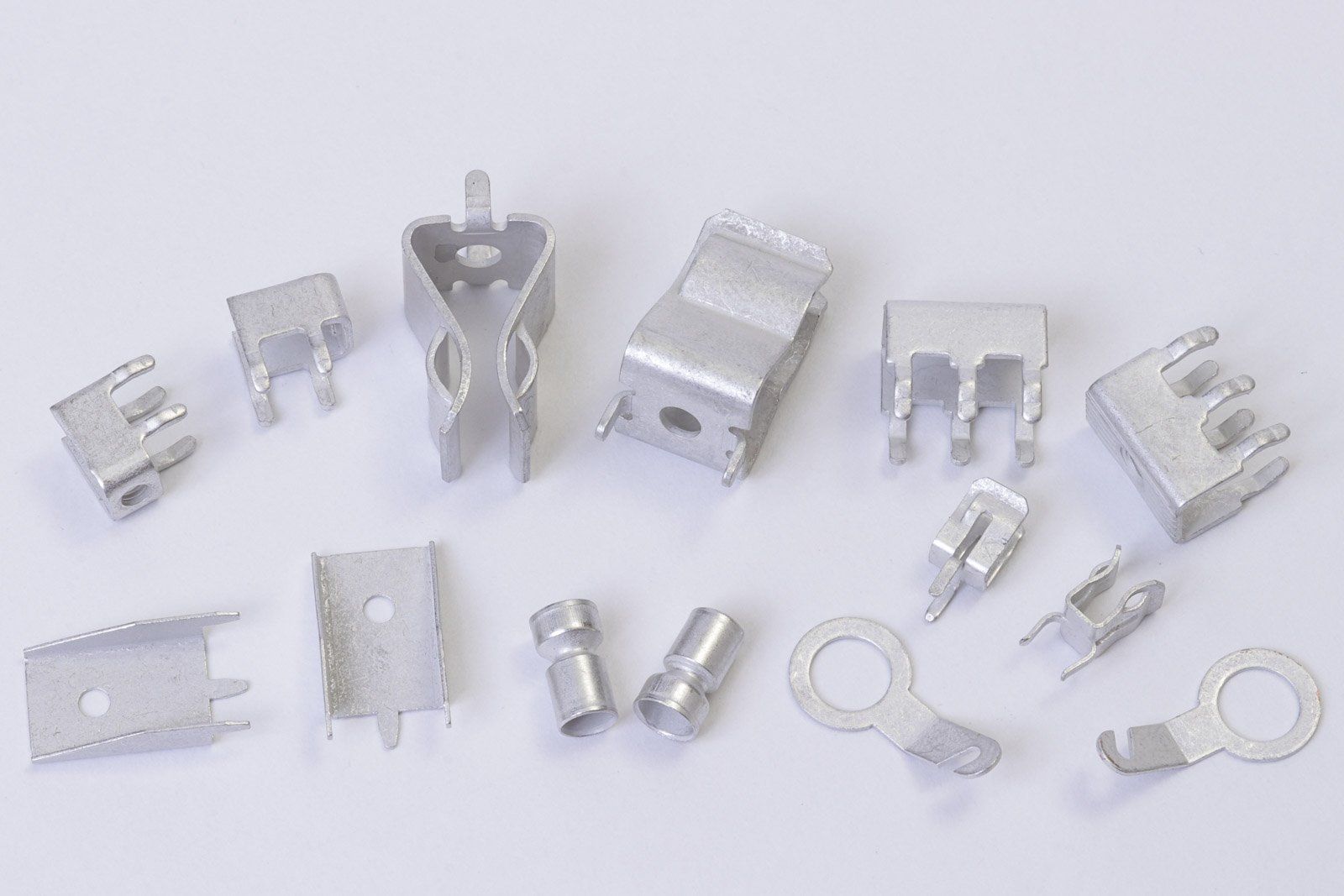

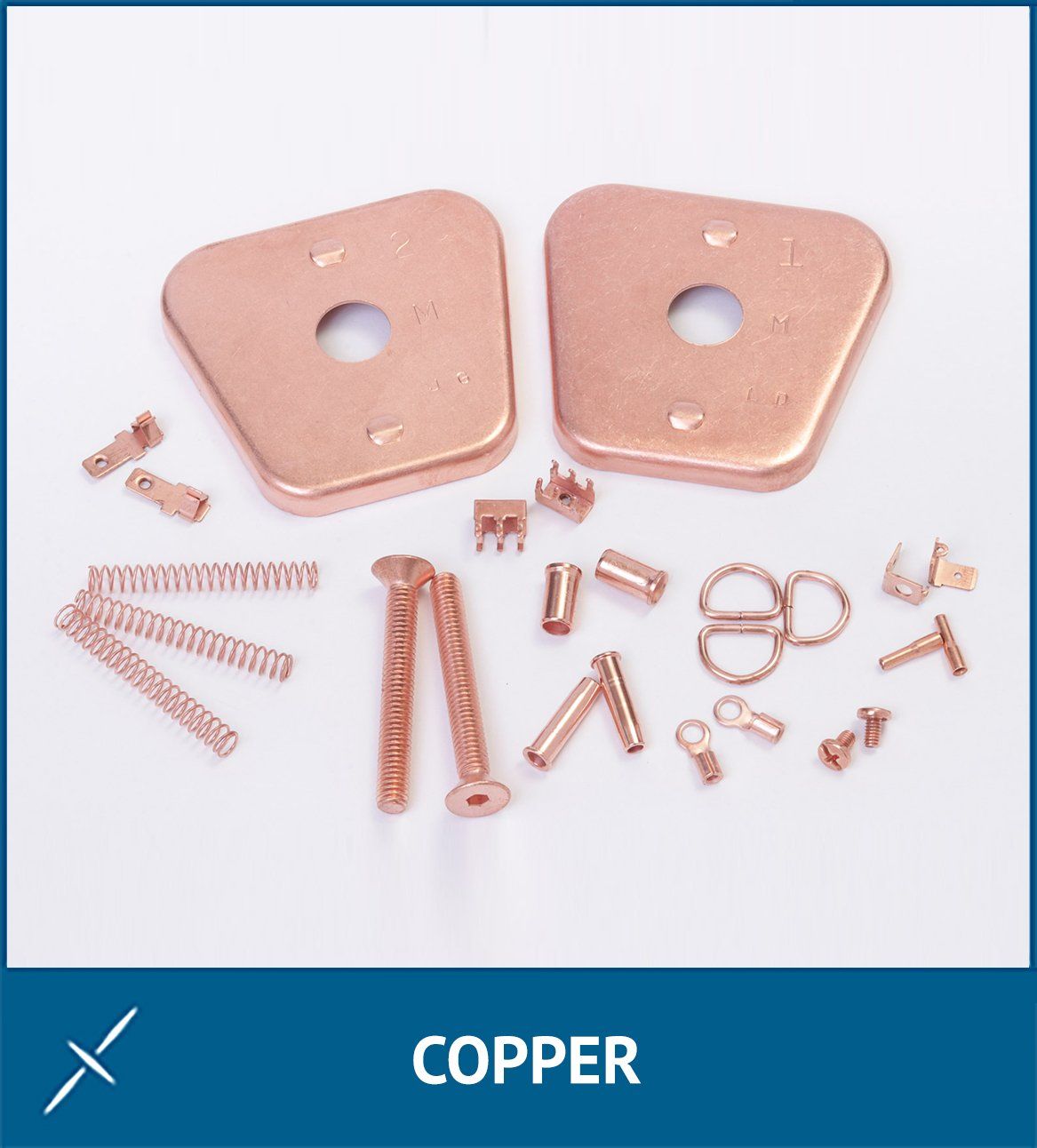

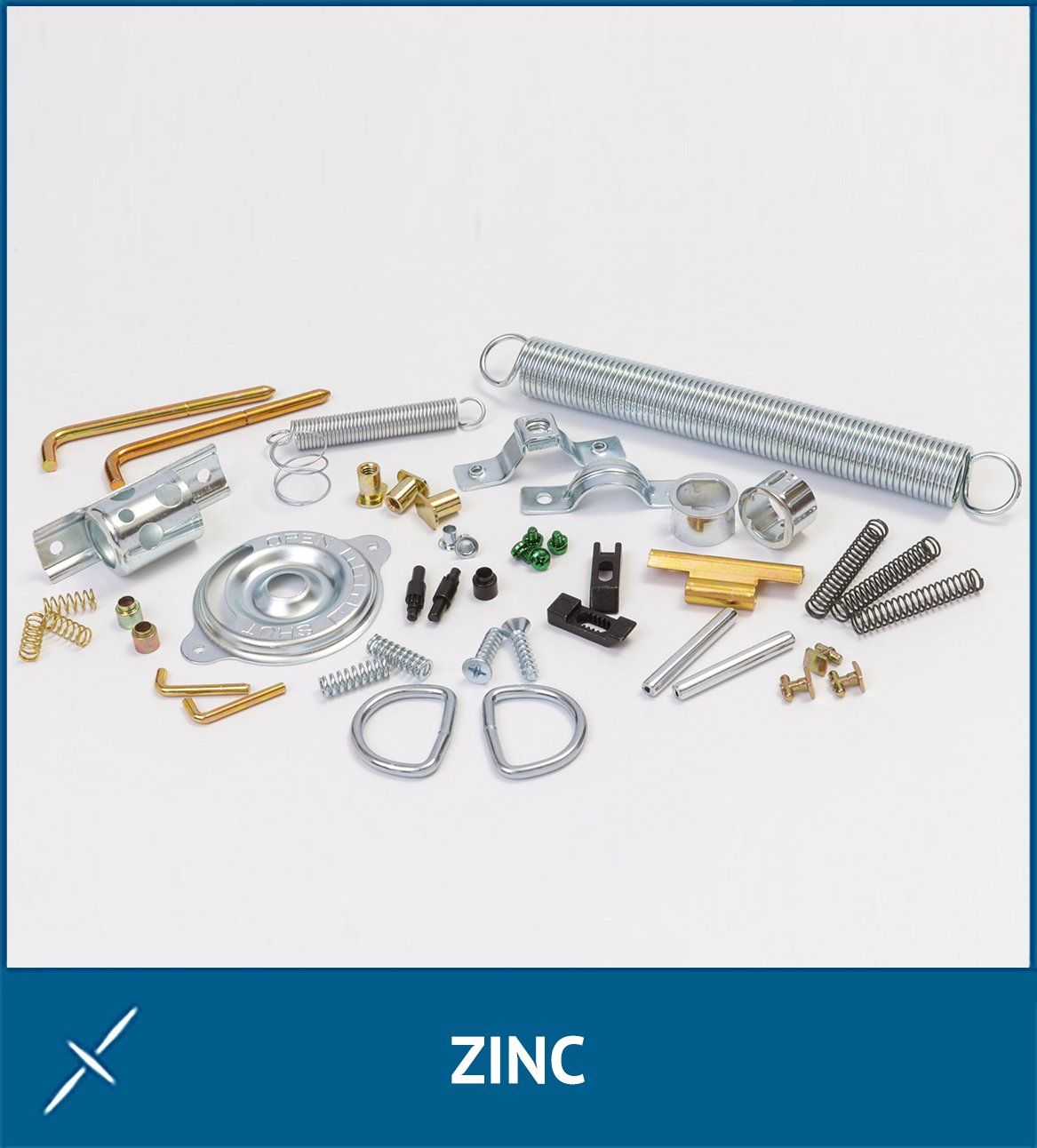

Tin electroplating can be deposited on a wide variety of metal substrates including iron, steel, nickel, copper, and their alloys.

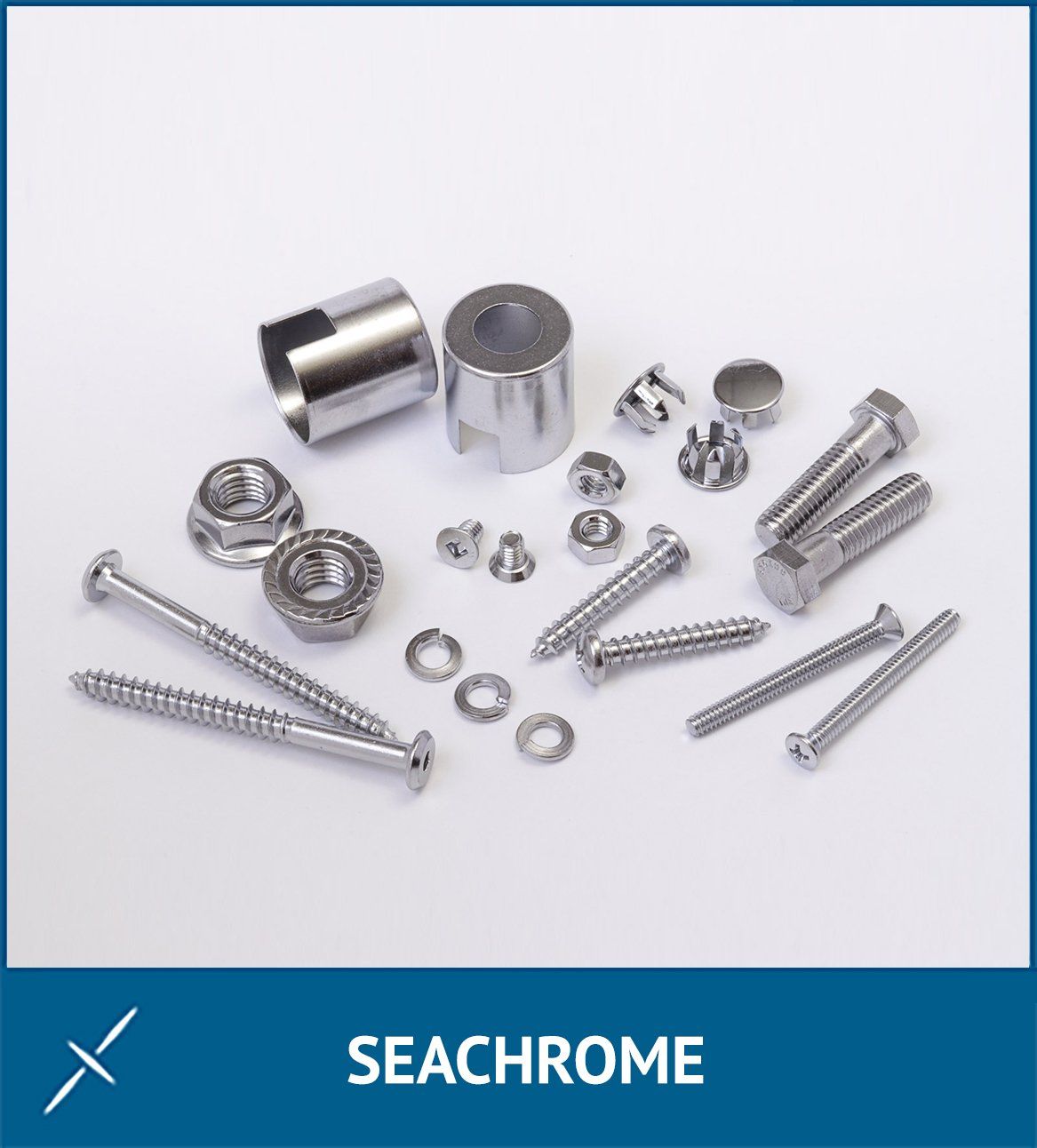

Our electroplated tin coating provides a surface finish that is resistant to tarnishing and corrosion in indoor applications. Some corrosion can be expected from tin coatings exposed outdoors. It is a non-toxic, 100% solderable, ductile and electrically conductive coating. Our bright deposits are smooth and mirror like while our matte deposits are flat and white to gray in appearance.

Tin coatings are not well-suited for low temperature applications particularly below -40o C which can lead to loss of adhesion. Tin plating is used in a wide range of electronic and automotive applications. Northeast Metal Works can accommodate the full range of minimum thickness requirements for Class A through E applications.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are a leading supplier of tin electroplated coatings for utility pole connectors. This is a high demand, quick response business in which utilities need to respond quickly to downed power lines in the wake of a major storm. Northeast Metal Works won this business due to our ability to respond in these demanding situations.

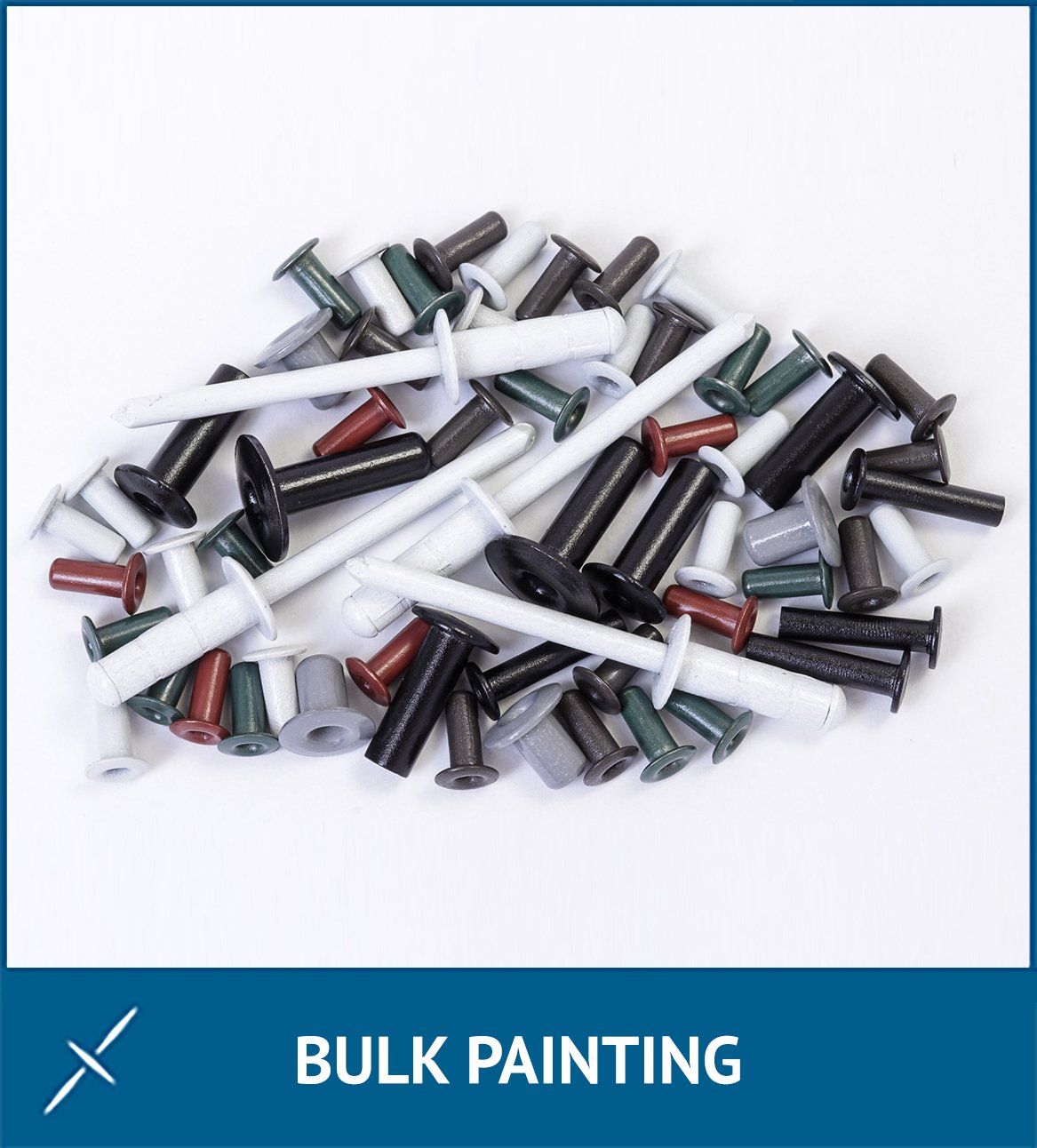

We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our tin plating and post-plating processes. We offer quick turnarounds on our high volume barrel plating lines.

For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Tin Plating Specifications and Certifications

Northeast Metal Works tin plating service is fully registered to ISO9001:2015 and complies with ASTM B545-13 and Ford WSB-M1P10-B and WSB-M1P11-B.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications with its tin plating service including:

Markets:

Automotive

Industrial

Electronic

Applications:

Electronic, electrical devices

Component parts

Metal fabrications

Substrates:

Ferrous

Non-Ferrous