METAL PLATING

TIN-NICKEL PLATING SERVICES

TIN-NICKEL

Our tin nickel plating service provides an attractive faint pinkish finish that is resistant to tarnish. It is typically used with a base coat of copper, brass or nickel and offers excellent corrosion resistance when coupled with these base layers.

It offers a replacement or an alternative to decorative chromium plating for a number of indoor and outdoor hardware, electrical and electronic accessories.

The alloy can retain an oil film on its surface making it useful in applications such as automotive braking systems, heavy-duty switch gears and mixing valves. The alloy has also found application in printed circuit boards because of the excellent throwing power of its solutions.

Tin nickel alloy is an inter-metallic compound of approximately 65% tin and 35% nickel. It is moderately ductile, solderable and free of internal stress. Tin nickel plating has also been found to be an effective replacement for nickel where nickel dermatitis is a concern.

Finish and Processing Options

Barrel Electroplated Tin Nickel Coatings

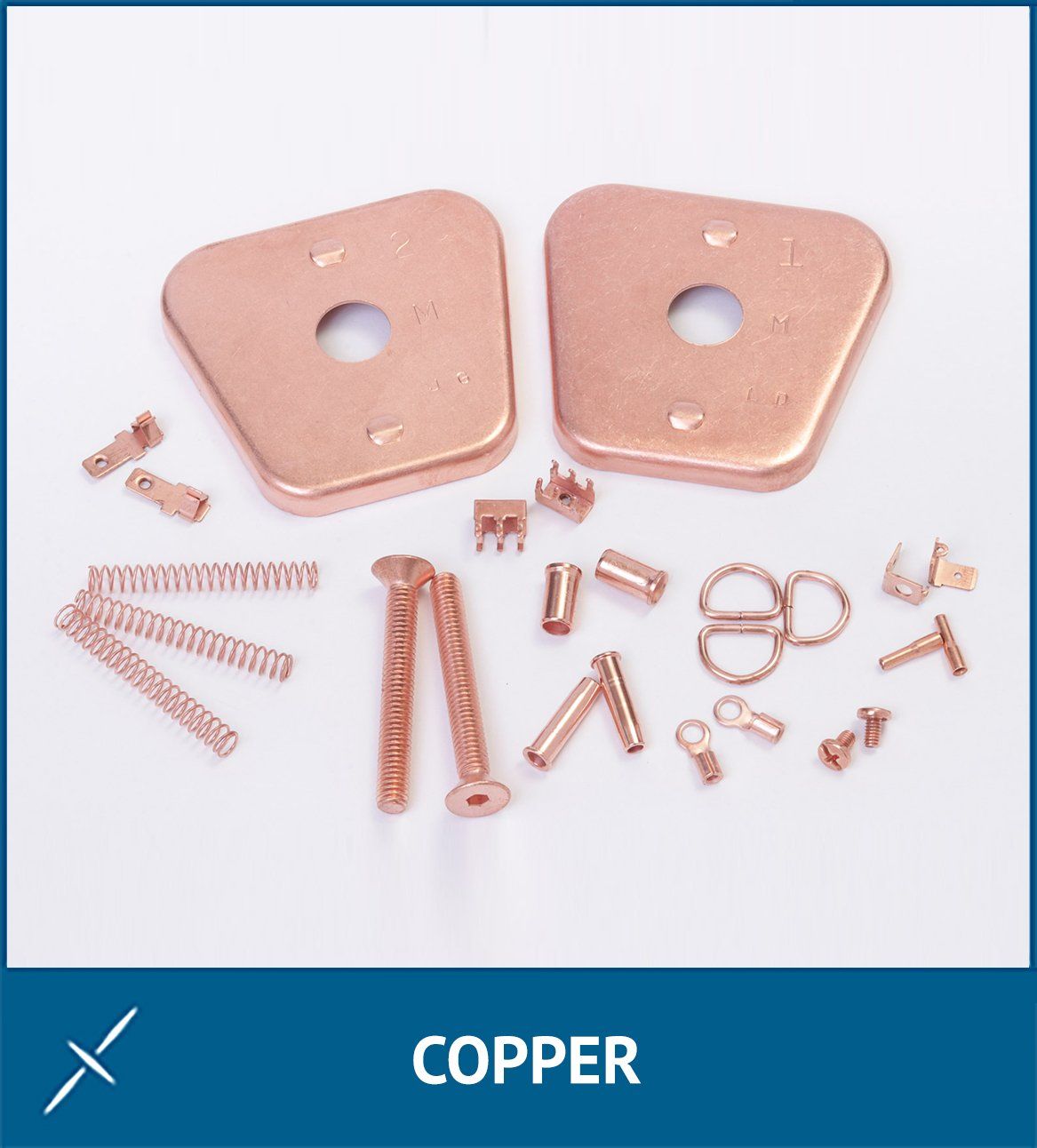

Tin nickel electroplating aka nickel tin plating can be deposited on a wide variety of metal substrates including steel, nickel, copper and copper-based alloys. Iron and steel parts may undergo pre- and post-coating treatments for reducing the risk of hydrogen embrittlement. Northeast Metal Works offers the advantage of high volume processing on our barrel electroplating tin nickel line.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success. We are a leading supplier of tin nickel electroplated coatings for several electronic component applications where quality and consistency are paramount.

Tin Nickel electroplated coatings are highly technical requiring in-depth know-how which is why Northeast Metals Works is the right fit for this critical application. We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes. We offer quick turnarounds on our high volume barrel plating lines.

For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Specifications and Certifications

Northeast Metal Works tin nickel plating is fully registered to ISO9001:2015 and complies with ASTM B605-95a.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications with its electroplated tin nickel coatings including:

Markets:

Automotive

Industrial

Electronic

Electrical

Applications:

Electronic, electrical devices such a printed circuit boards

Component parts

Metal fabrications

Substrates:

Ferrous

Non-Ferrous