METAL PLATING

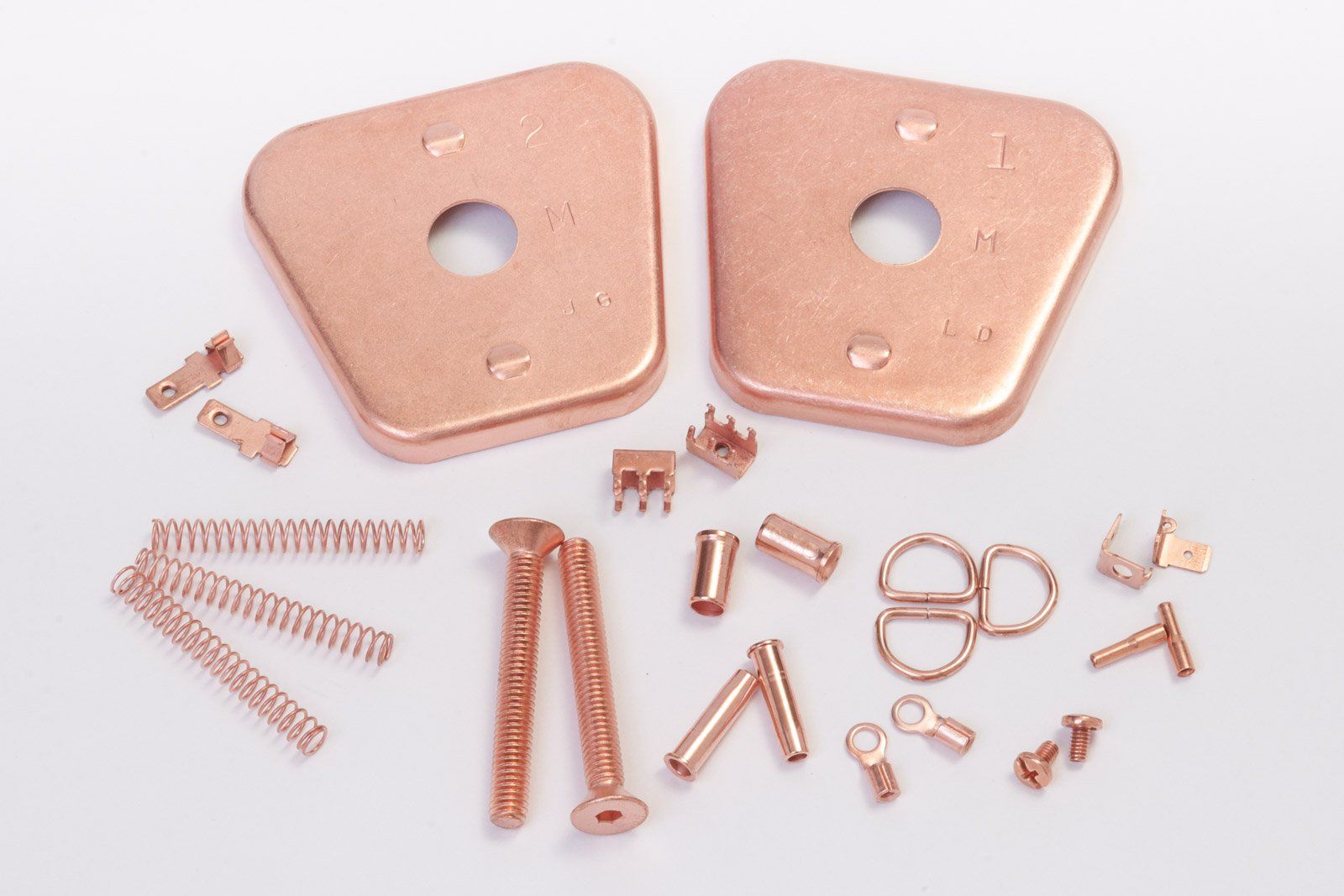

COPPER PLATING SERVICES

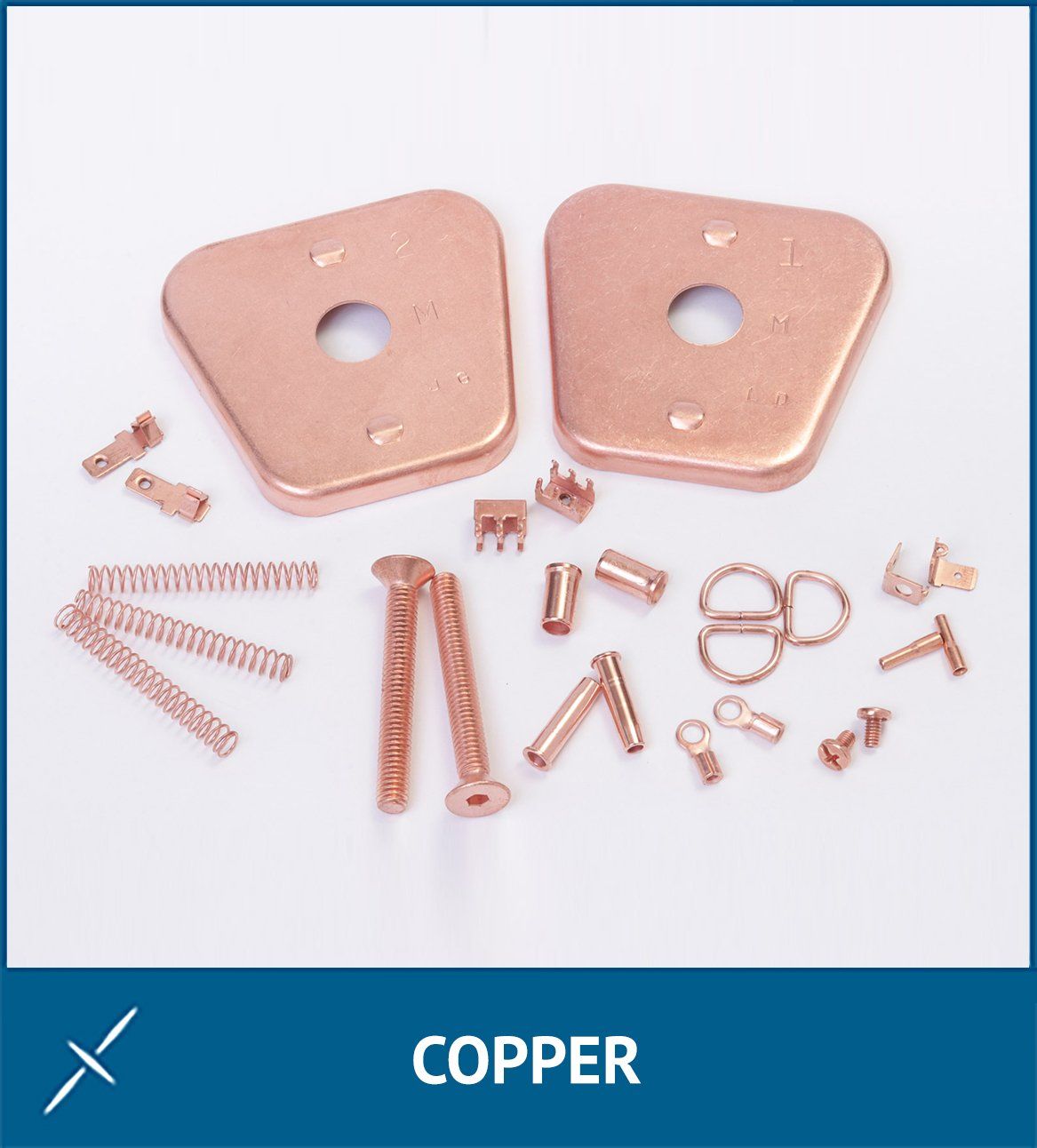

COPPER

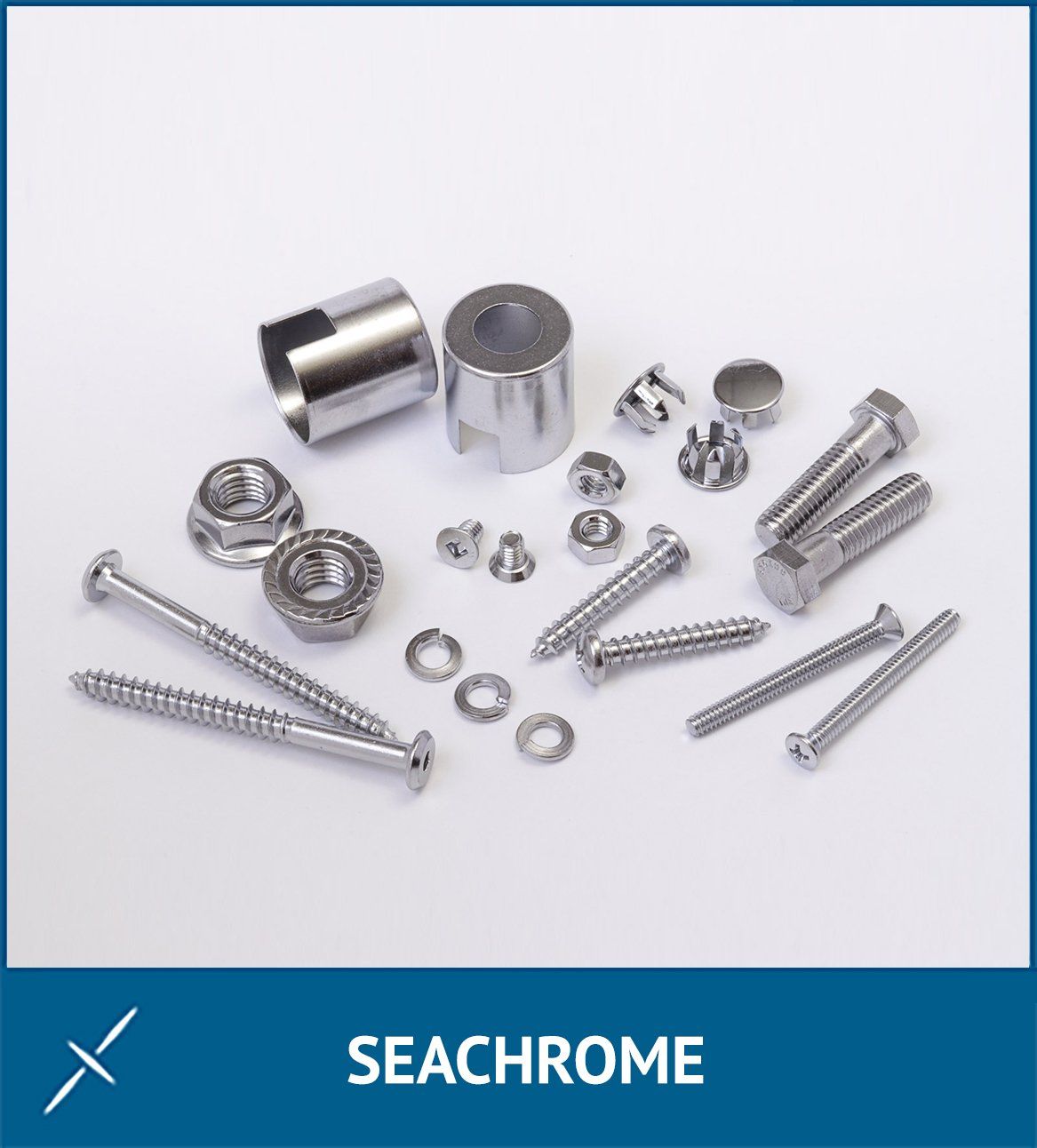

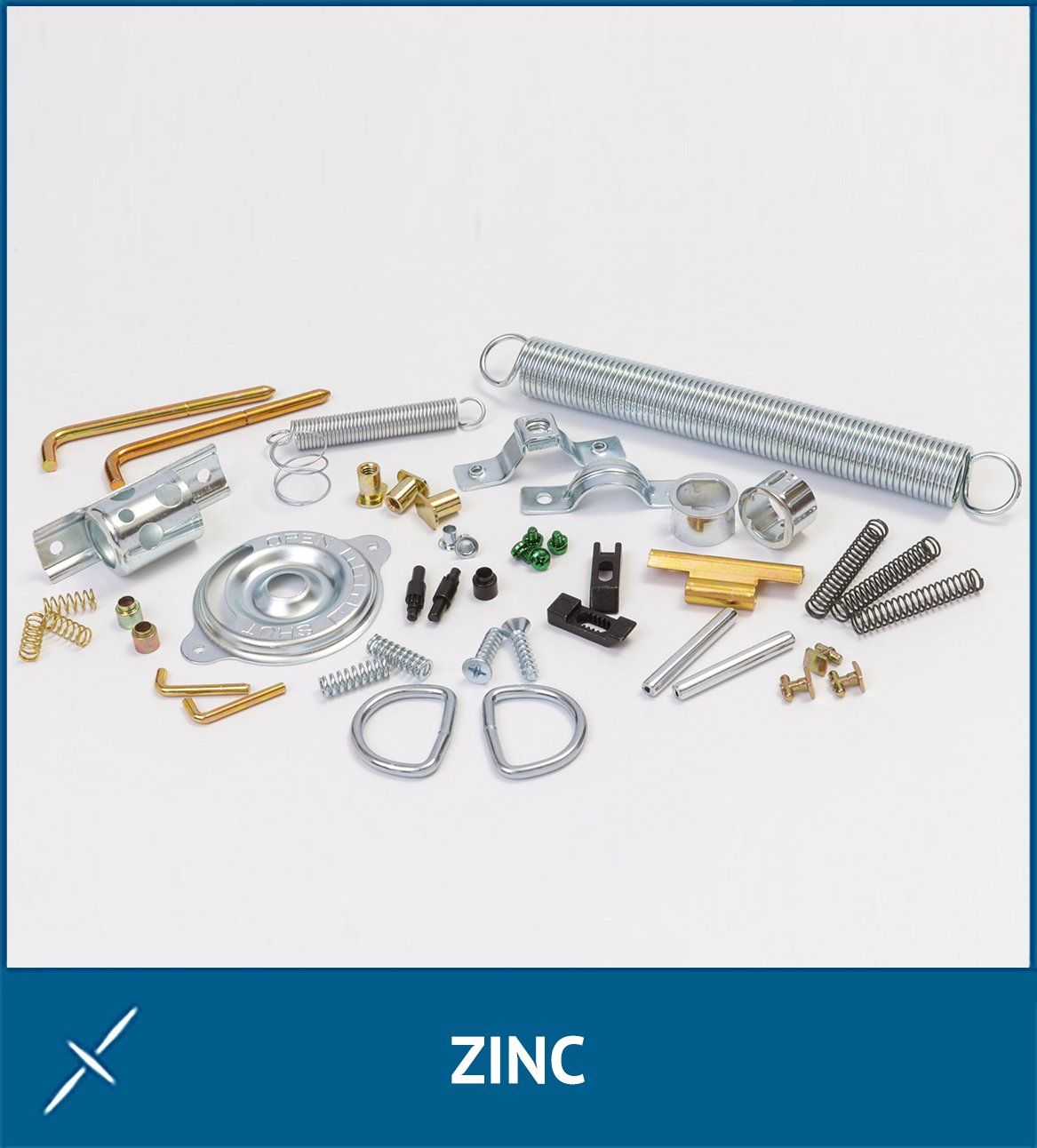

Our copper plating service is primarily used as an undercoat rather than as a cosmetic finish. We meet all of the standards for electrodeposited copper for engineering uses such as surface hardening, heat treatment stop-off, as an underplate for other engineering coatings, for electromagnetic interference shielding in electronic circuitry and in certain joining operations.

Finish and Processing Options

Electroplated Copper Coatings

We offer cost-effective high-volume barrel copper plating in our automated copper plating line. Copper electroplating provides a layer of corrosion resistance on steel. Our electroplated copper coatings can be varied in appearance from a bronze matte finish to a shiny color depending on the application. The great adhesion properties of our electroplated copper coatings provide an excellent base coat for tin and nickel and an excellent electrical conductor in many electronics applications.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are the leading supplier of copper electroplated coatings for demanding aerospace applications such as brake linings. It is our ability to deliver consistent quality at high volume that has allowed us to service this important market. We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes.

We offer quick turnarounds on our high volume barrel plating lines. For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks.

Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Copper Plating Specifications and Certifications

Northeast Metal Works copper electroplating service is fully registered to ISO9001:2015 and is capable of meeting specifications ASTM B-734-97 and Ford ESF-M1P30-A.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications with its electroplated copper coatings including:

Markets:

Automotive

Military

Aerospace

Industrial

Electronic

Applications:

Electronic devices

Component parts

Metal fabrications

Substrates:

Ferrous

Non-Ferrous