METAL PLATING

ZINC PLATING SERVICES

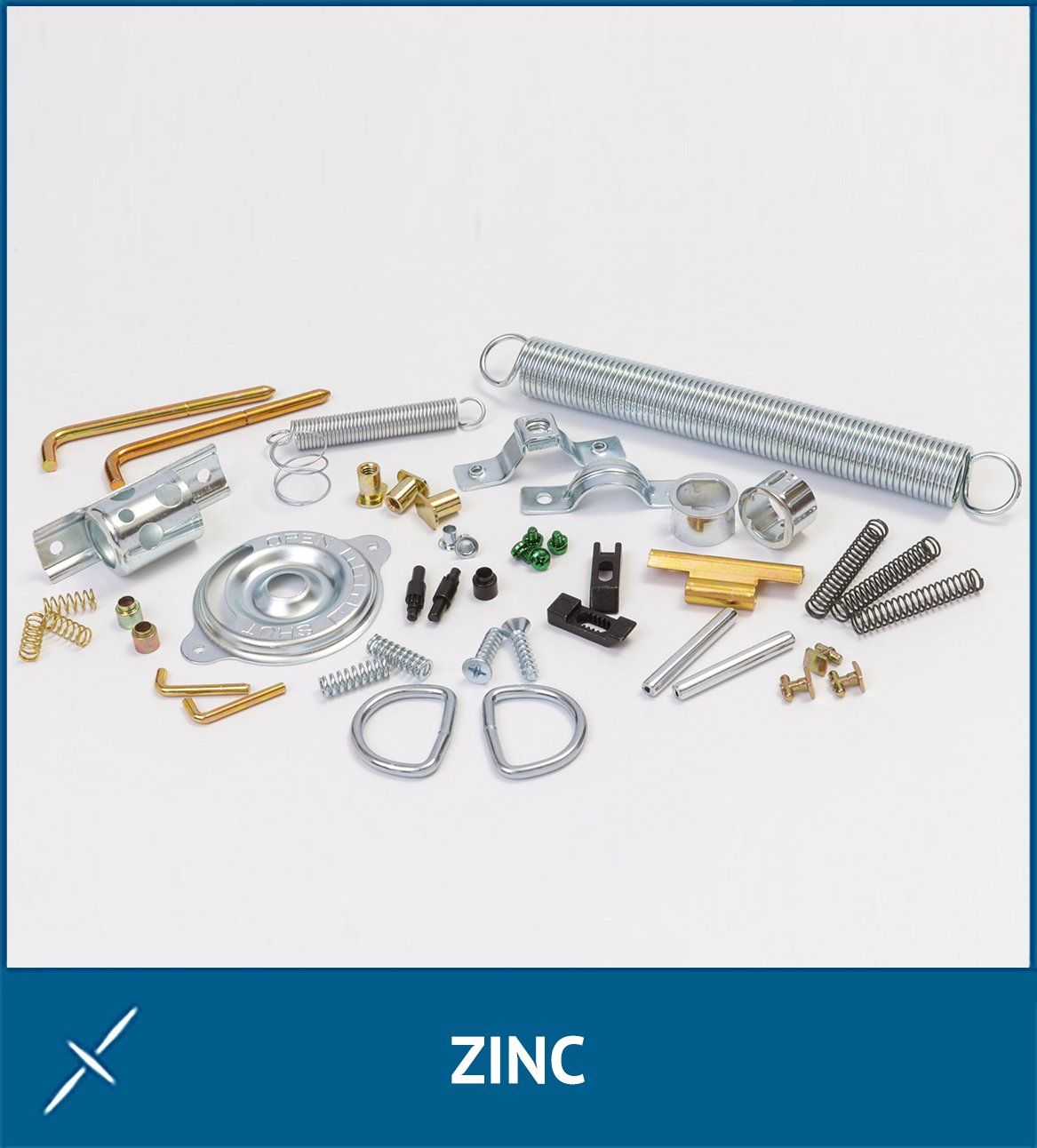

ZINC

Our zinc plating services provide an environmentally friendly and cost-effective way to protect metals such as carbon steel and brass from corrosion. Zinc plating or “electroplating” acts as a sacrificial anode to protect the substrate.

Zinc plating offers many advantages including excellent ductility and adhesion, superior corrosion protection, a low stress deposit with excellent throwing power and outstanding receptivity of chromate conversion coatings.

Zinc Finish and Processing Options

Barrel and Rack Plating

One of the advantages offered by Northeast Metal Works is our ability to accommodate multiple part designs with our capability to apply electroplated zinc coatings on either our barrel zinc electroplating line or our rack zinc electroplating line. High volume parts that can be processed in bulk are good candidates for our barrel zinc electroplating lines.

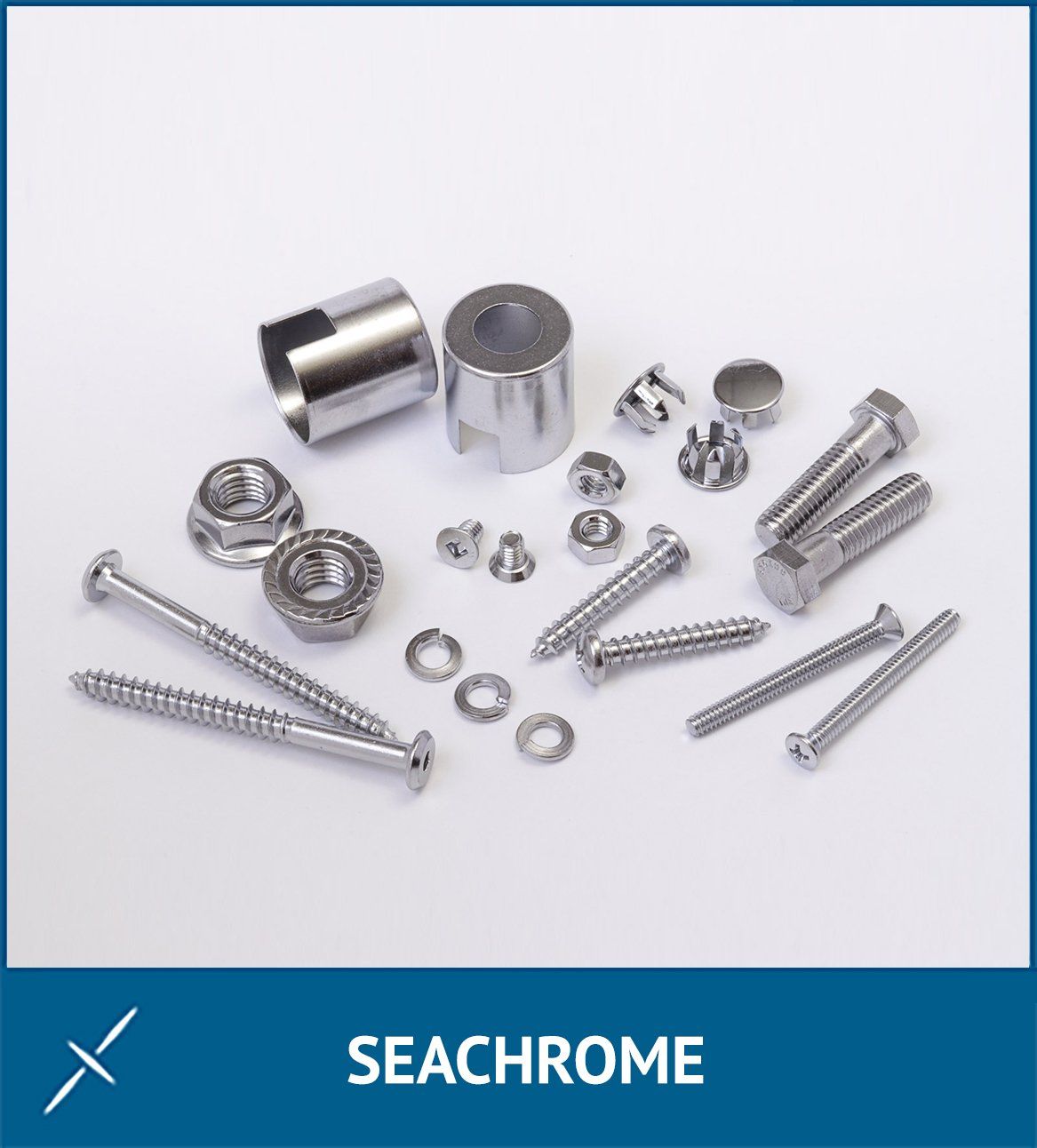

While more intricate part designs or heavy parts can be individually processed on our automatic rack zinc electroplating line. Zinc plating is applied to many different types of small parts including fasteners, nuts, bolts, springs and many others.

Acid and Alkaline Zinc Electroplated Coating

Northeast Metal Works is unique in that we operate both acid-based and alkaline-based zinc electroplating lines so that we can accommodate effective plating of your parts. Both finishes provide a durable, environmentally-friendly and cost-effective way to protect your steel and other metal parts. Both types of plating offer a bright attractive finish with good ability to be chromated.

Alkaline zinc is the electroplated zinc coating preferred for zinc plating a bright zinc finish in deep recesses or inner diameters of parts where high throwing power is required. Acid-zinc electroplated coatings tend to be the better option when zinc plating heat-treated steel parts.

Conversion Coatings and RoHS Compliance

In order to comply with EU directives, Northeast Metal Works offers both trivalent (RoHS compliant) and hexavalent (non-RoHS compliant) chromium conversion coatings. These coatings not only enhance the corrosion resistance of the zinc but can also alter the zinc coating’s cosmetic appearance. In trivalent chromium, we offer a bright bluish (clear), yellow, green or black finish while in hexavalent chromium we offer a yellow, olive drab or black finish. In addition, we have the ability to passivate the electroplated zinc coating using the chromating process to help prevent corrosion and pitting.

Corrosion Resistance Testing

Northeast Metals Works zinc plating service has the capability to perform salt spray corrosion resistance testing according to ASTM B117 on our finished parts. Electroplated zinc coated carbon steel parts with a trivalent chromium conversion coating or a hexavalent chromium coating typically achieve 72 to 400 hours of protection against attack on the substrate in the salt spray test.

Baking

Northeast Metal Works operates several furnaces for the purpose of relieving hydrogen to avoid hydrogen embrittlement in zinc-coated parts according to customer specifications.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

As a result of our service excellence, we have been able to partner with high-volume automotive suppliers because of our excellent quality systems, responsiveness and our ability to meet their high volume demand for zinc electroplating services when their end customers need material. We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes.

We offer quick turnarounds on our high volume barrel plating lines. For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Zinc Plating Specifications and Certifications

Northeast Metal Works zinc plating service is fully registered to ISO9001:2015 and is capable of meeting specifications ASTM B-633, ASTM B-840, Delphi DX551200, GMW3044M, GM4345M, Ford ESF-M1P41-A, Ford ESS-M1P45-A, Ford WSD-M1P85-A1, Ford WSD-M1P85-A2, Ford WSD-M1P85-A3 and Nissan NES M4040 with its zinc coating process.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications with its electroplated zinc coatings including:

Markets:

Automotive

Medical

Military

Aerospace

Industrial

Chemical Process Industry

Textile

Marine

Electronic

Applications:

Fasteners

Bolts

Washers

Medical devices

Dental devices

Component parts

Metal fabrications

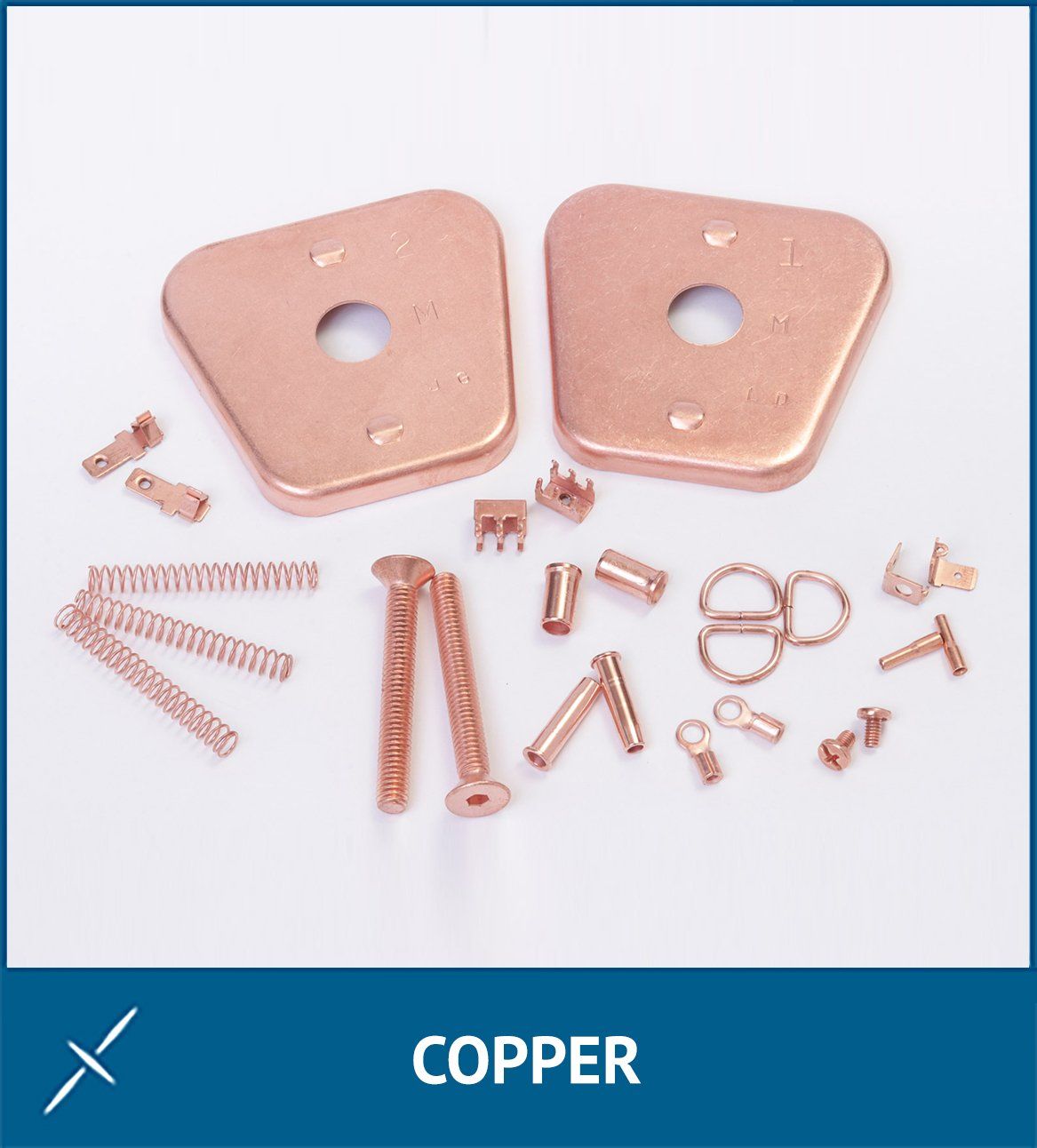

Substrates:

Ferrous

Non-Ferrous