METAL PLATING

ZINC-NICKEL PLATING SERVICES

ZINC-NICKEL

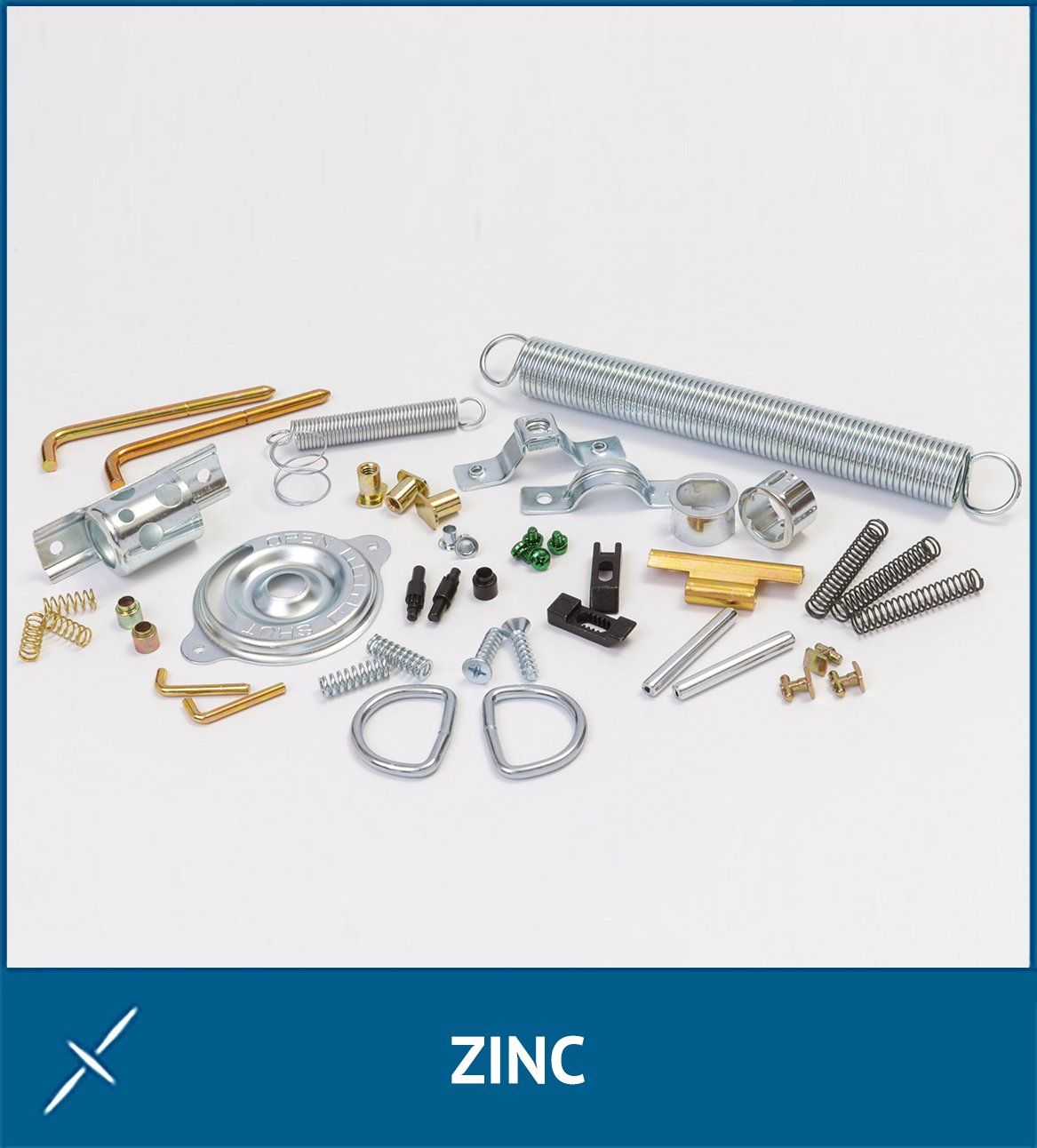

Our zinc nickel plating service provides a coating that offers greater corrosion protection, more wear resistance and limits the thermal stress to parts subjected to higher operating temperatures than zinc electroplated coatings alone.

Electroplated Zn-Ni coatings also have good throwing power to better coat blind holes and recesses. Zn-Ni alloy coatings are usually composed of approximately 85% zinc and 15% nickel and quite often are used as a base layer under trivalent chromium. zinc nickel plating typically has a dull gray finish in its alloy form but can be chromated to a black zinc finish.

Finish and Processing Options

Barrel Electroplated Zinc Nickel Coatings

Zinc nickel electroplating is typically deposited on iron and steels. Northeast Metal Works offers the advantage of high volume processing on our barrel zinc nickel plating line.

Corrosion Resistance

Northeast Metals Works zinc nickel plating service has the capability to perform salt spray corrosion resistance testing according to ASTM B117 on our finished parts. Electroplated zinc nickel coated carbon steel parts with a trivalent chromium conversion coating typically achieve up to 1000 hours of protection against attack on the substrate in the salt spray test.

The Northeast Metal Works Service Difference

Located in central Connecticut, we have been servicing metal stamping and component manufacturers from across the United States for decades at our Waterbury Plating and Pape Electroplating businesses. Service is the key to our success.

We are critical supplier of zinc nickel electroplating for one high volume automotive supplier of rivets and fasteners who demands outstanding quality at competitive prices, automotive industry compliant quality systems and the ability to react quickly to their ever-changing, high volume demands. We are a “one-stop” shop able to manage the logistics of your finishing needs from cleaning through third-party heat treatment and, finally, through our plating and post-plating processes.

We offer quick turnarounds on our high volume barrel plating lines. For customers in our geographic area, we offer pick-up and delivery at your doorstep in our own dedicated fleet of trucks. Our management collectively has over 100 years of experience in the metal plating business. We can put that knowledge to work for you to solve your most demanding surface finish challenges.

Zinc Nickel Plating Specifications and Certifications

Northeast Metal Works zinc nickel plating service is fully registered to ISO9001:2015 and complies with ASTM B841-99.

Markets and Applications

Northeast Metal Works has served a broad range of customers, markets and applications for its zinc nickel plating service including:

Markets:

Automotive

Medical

Military

Aerospace

Industrial

Chemical Process Industry

Textile

Marine

Electronic

Applications:

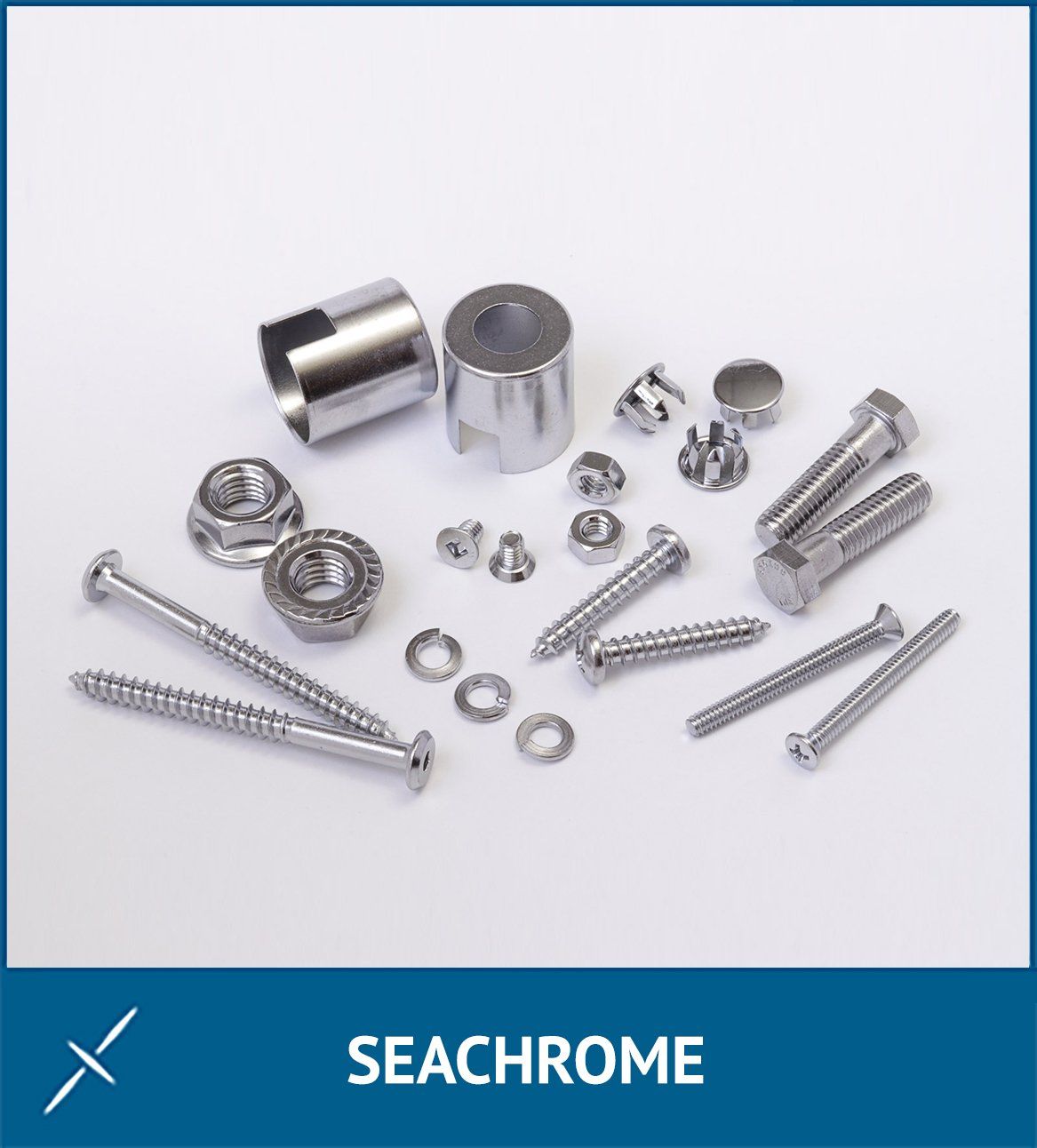

Fasteners

Bolts

Washers

Medical devices

Dental devices

Component parts

Substrates:

Ferrous